In the days before film rolls and digital sensors, photography relied on glass, chemistry, and precision. The glass plate photography era—spanning the mid-19th to early 20th century—produced some of the most detailed and enduring images in photographic history. This period not only revolutionized how people captured the world but also laid foundational standards for modern optics and materials, including the evolution of float glass manufacture.

This article explores six essential tools used in the glass plate photography era. Each one played a pivotal role in producing high-quality, chemically stable, and long-lasting photographic images. Along the way, we’ll highlight how this legacy influenced the development of the float glass industries we rely on today.

To learn more about the significance and evolution of this technique, visit our in-depth guide on glass plate photography.

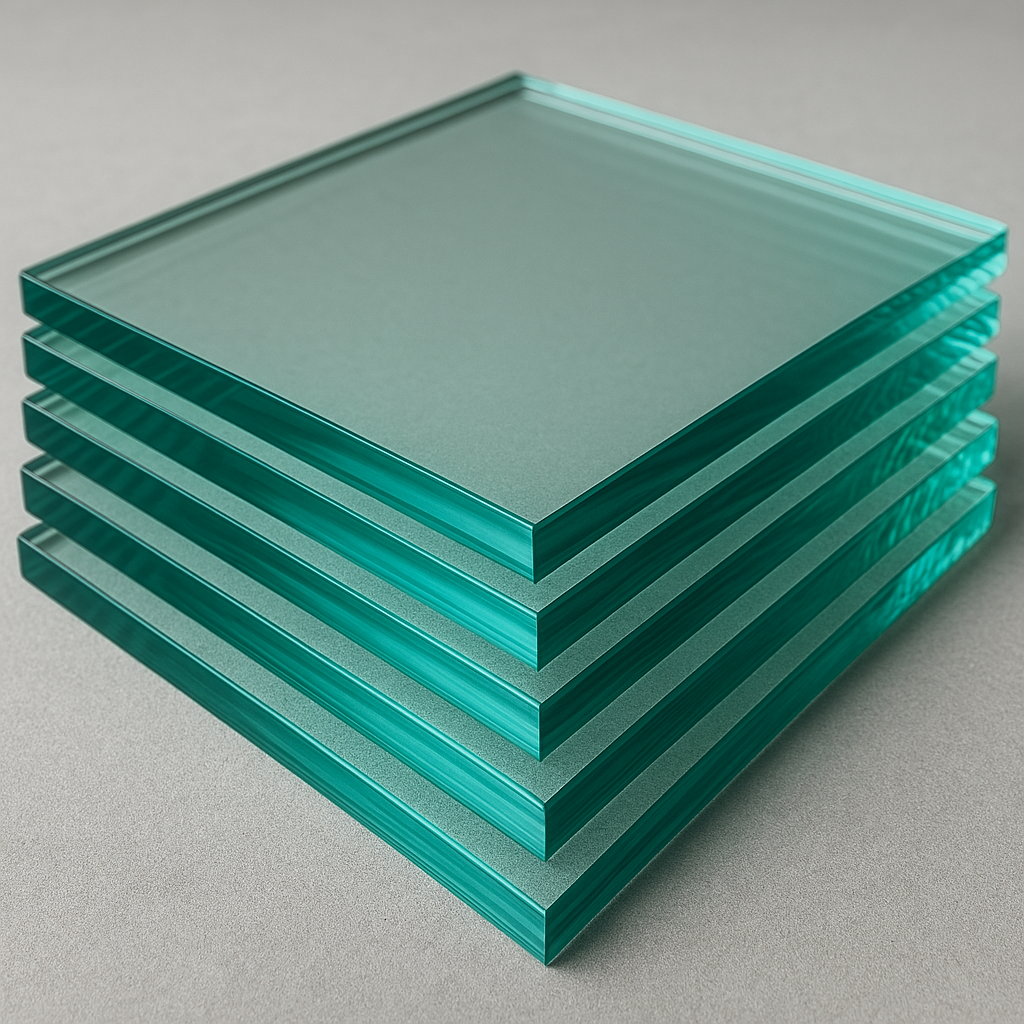

1. Glass Plates: The Foundation of the Process

The most essential tool in glass plate photography was the glass plate itself. These rectangular sheets of high-quality glass served as the image capture surface, coated with light-sensitive chemicals to form either negatives or positives.

Why Glass Plates Were Revolutionary:

- Provided a perfectly flat, stable medium for exposure

- Offered unparalleled image clarity and resolution

- Enabled long-term image preservation without warping

- Inspired advancements in flat glass production, including clear float glass

Early plates had to meet extremely high standards for smoothness, consistency, and chemical resistance. These demands directly influenced the birth of float glass technologies later in the 20th century, and modern manufacturers like Emirates Float Glass continue to uphold the precision once required for photography.

2. Plate Holders: Precision in Loading and Exposure

Once coated, the fragile glass plates needed to be securely housed inside plate holders, which were inserted into large-format cameras. These holders kept the plates light-tight before exposure and ensured alignment within the camera.

Features of Plate Holders:

- Typically made of wood with metal hinges

- Designed to hold one or two plates at a time

- Contained dark slides to protect emulsions from accidental exposure

- Allowed quick swapping in the field for multiple exposures

Plate holders were crucial for portability and efficiency, especially in the field. For landscape or documentary photographers, managing fragile glass plate negatives without damaging them required both skill and high-quality equipment.

3. Large Format Cameras: Designed for Detail

Glass plate photography relied on large format view cameras to capture the full detail possible with the medium. These cameras, often mounted on tripods, used ground glass for focusing and bellows for extending focal length.

Key Camera Features:

- Customizable for different focal lengths and lenses

- Provided adjustable tilt, shift, and rise for architectural correction

- Used ground-glass focusing screens to preview the image before exposure

- Designed to accommodate various plate sizes, from 4×5 inches to 11×14 inches and beyond

The clarity and resolution achieved with these cameras were unmatched—some images are still usable today for digital archiving due to their incredible detail. This pursuit of perfection also helped influence the float glass industries to prioritize optical quality and flatness.

4. Collodion and Emulsion Chemistry Kits

Before dry plates became standard, wet plate photographers needed portable chemical kits to prepare and develop images on-site. These included bottles of collodion, silver nitrate, developers, fixers, and varnishes.

What Was Included:

- Collodion solution: Containing cellulose nitrate dissolved in ether and alcohol

- Silver nitrate bath: To sensitize the plate

- Developer and fixer: Usually iron-based and hypo solutions

- Varnishes: To seal and protect the final image

Working with these chemicals required extreme precision and care. Improper mixing or contamination would ruin an image. The need for clean, non-reactive surfaces led to stricter standards for glassmaking—foreshadowing the technical requirements in modern float glass manufacture.

5. Darkroom Equipment: Where Images Came to Life

Once exposed, the plates had to be developed in a darkroom—a lightproof environment where chemical reactions could occur safely. This space was critical for controlling the photographic process from start to finish.

Darkroom Essentials Included:

- Safelights: Usually red or amber, to prevent exposure of sensitive emulsions

- Developing trays and tanks: Made of glass, porcelain, or early plastics

- Drying racks: To air-dry the plates after washing

- Measuring tools: For accurate chemical proportions and temperature control

Darkrooms also served as laboratories for experimentation, where photographers tested different exposures, emulsions, and processing techniques. The refinement of these practices paralleled the precision later demanded in float glass industries for electronics, optics, and building materials.

6. Storage Systems: Protecting the Legacy

Given the fragile nature of glass, safe storage was essential. Archival boxes, wooden cases, and metal racks were used to protect glass plate negatives from scratches, breakage, and environmental degradation.

Characteristics of Proper Storage:

- Vertical stacking to reduce weight pressure

- Buffered materials to protect emulsion layers

- Climate control to prevent warping, mold, or silver tarnishing

- Cataloging systems for organizing large archives

Many museums and libraries today still use these original storage methods to protect 19th-century plates. Thanks to these systems, thousands of historical images have been preserved, many of which are being digitized using modern clear float glass scanning surfaces for optical accuracy.

Lasting Influence on the Glass Industry

The tools and techniques of glass plate photography did more than shape visual history—they also laid the groundwork for precision glassmaking. The stringent requirements for optical quality, chemical stability, and structural consistency became benchmarks for producing architectural and industrial glass.

These standards are still followed today in float glass manufacture, where sheets of molten glass are floated on tin to create flawless panes. Modern producers such as Emirates Float Glass and Mediterranean float glass manufacturers continue to build on the legacy of photographers who demanded perfection from their glass.

Applications of Float Glass Today:

- Architectural windows and curtain walls

- Solar panels and green building systems

- High-resolution electronics and displays

- Medical and scientific optics

These uses reflect how the legacy of photographic innovation lives on in every polished, high-performance glass surface around us.

Conclusion: Tools That Transformed More Than Photography

Each tool used during the glass plate photography era—from the glass plates themselves to the chemical kits and darkrooms—was part of a pioneering process that changed how we capture, preserve, and see the world. The craftsmanship, technical demands, and scientific rigor of the time didn’t just advance photography—they helped refine the very glass we use today in architecture, technology, and energy.

Whether you’re a historian, artist, or engineer, understanding the tools behind this early photographic era offers valuable insight into the cross-section of art and industry. For a deeper dive into how these tools evolved, check out our complete guide to glass plate photography and its modern-day influence on float glass production.