Understanding the Role of Materials in Insulating Glass Units

An Insulating Glass Unit (IGU) plays a pivotal role in modern architecture by providing superior thermal insulation, acoustic performance, and enhanced comfort. At the heart of its effectiveness lie two critical components: spacers and sealants. These materials significantly influence the IGU’s lifespan, energy efficiency, and resistance to environmental elements. Selecting the right spacer and sealant is essential for optimizing IGU performance and achieving long-term sustainability.

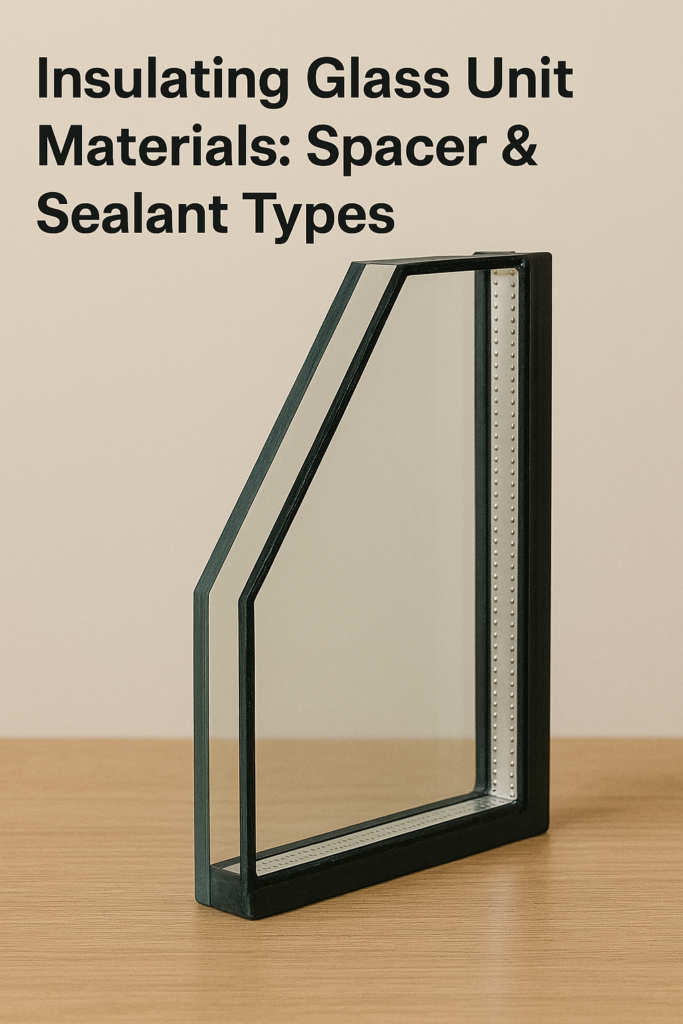

Anatomy of an Insulating Glass Unit

An IGU typically comprises:

- Two or more panes of glass

- A spacer bar separating the panes

- Desiccant within the spacer

- A primary sealant for moisture resistance

- A secondary sealant for structural strength

Understanding each component’s function—especially the spacer and sealants—helps inform better choices during Insulating Glass Unit installation.

Spacer Types and Their Impact on IGU Performance

What is a Spacer in an IGU?

The spacer is the component that maintains uniform separation between the panes of glass, creating an insulating air or gas space. It also houses the desiccant, which absorbs any residual moisture.

Common Spacer Materials

1. Aluminum Spacers

Aluminum has been widely used due to its strength and affordability. However, it has high thermal conductivity, which can result in thermal bridging.

Pros:

- Durable and low-cost

- Easy to manufacture

Cons:

- High heat transfer

- Can cause condensation at window edges

2. Stainless Steel Spacers

Stainless steel offers better thermal resistance than aluminum while maintaining structural integrity.

Pros:

- Better thermal efficiency

- Durable and strong

Cons:

- Higher cost

- More complex to fabricate

3. Warm Edge Spacers (Foam or Thermoplastic)

These are non-metallic spacers that dramatically improve the IGU’s thermal performance.

Pros:

- Reduced heat loss

- Lower risk of condensation

- Improved comfort

Cons:

- May have lower structural strength

- Limited lifespan in extreme conditions

Warm edge technology supports modern sustainability goals, contributing to Insulating Glass Unit benefits such as energy savings. For detailed advantages, explore Insulating Glass Unit Benefits for Energy Savings.

Sealant Types for IGUs

Why Sealants Matter

Sealants ensure the structural integrity of the IGU and prevent moisture ingress and gas leakage. A reliable sealant prolongs the unit’s life and maintains its insulating properties.

Primary Sealants

Used for moisture resistance and adhesion between the spacer and glass.

Common Types:

- Polyisobutylene (PIB): Excellent moisture resistance, low permeability

Secondary Sealants

Provide mechanical strength and protect the unit against external forces.

Common Types:

- Silicone: High UV resistance, flexible

- Polysulfide: Strong bonding, good chemical resistance

- Polyurethane: Economical, moderate performance

The combination of primary and secondary sealants ensures the Insulating Glass Unit maintenance remains minimal while extending its functional life.

Material Considerations During IGU Installation

Factors to Consider

- Climate conditions

- Building use (residential, commercial, institutional)

- Glass type and coating

- Spacer and sealant compatibility

Professional Insulating Glass Unit installation includes an assessment of all these variables. Using high-performance materials aligned with building needs guarantees long-term results.

Applications of IGUs With Quality Materials

Residential and Commercial Use

High-performance spacers and sealants ensure that IGUs in homes and offices provide lasting benefits such as energy efficiency and noise control. For comfort-focused applications, read Insulating Glass Unit for Comfortable Indoor Spaces.

Architectural and Scenic Integration

Advanced materials allow IGUs to support large panes with minimal visual disruption, enhancing daylighting and views. Explore how IGUs improve interiors at Insulating Glass Unit Enhances Daylight and Views.

IGUs in Landscape Design

Incorporating IGUs in landscape structures—like greenhouses, atriums, and outdoor living rooms—relies on robust sealants and thermally efficient spacers to handle variable environmental stresses. These innovative uses contribute to a Bright View Landscape Defined: What Makes It Stand Out?.

Sustainability and Environmental Impact

Enhancing IGU Sustainability With Material Selection

Using non-metallic spacers and low-emission sealants contributes to greener construction. Materials that resist gas loss and moisture penetration reduce the need for replacements, enhancing the Insulating Glass Unit sustainability profile.

Lifecycle Benefits

- Lower carbon footprint from energy savings

- Reduced material waste over time

- Compatibility with recyclable materials

Experience, Expertise, and Trustworthiness

Selecting the right materials is not just about product specs—it’s about working with experienced suppliers and installers who understand environmental performance, durability, and long-term value.

What to Look For:

- Certified thermal performance ratings

- Industry-recognized warranties

- Transparent material disclosures

Experts help ensure that every Insulating Glass Unit application—from skyscrapers to scenic gardens—meets performance, comfort, and aesthetic goals.

Conclusion

The performance and durability of an Insulating Glass Unit depend heavily on the choice of spacer and sealant materials. Whether for residential windows, commercial facades, or landscape-integrated spaces, selecting high-quality materials ensures superior insulation, extended life span, and reduced maintenance needs. Informed choices lead to better thermal performance, greater sustainability, and enhanced comfort, reinforcing the importance of professional guidance and trusted manufacturing in IGU projects.