As energy efficiency continues to play a pivotal role in building design and construction, the insulating glazing unit (IGU) has become a cornerstone of modern architectural solutions. While much attention is often given to glass types, gas fillings, or coatings, one critical component that is sometimes overlooked is the spacer.

Spacers may seem like a minor detail, but they have a major impact on an IGU’s thermal efficiency, longevity, and resistance to condensation. This article explores the various types of spacers used in IGUs and explains why choosing the right one is essential for optimal performance.

What is an Insulating Glazing Unit?

An insulating glazing unit is a multi-pane window system comprising two or more sheets of glass separated by a spacer. The spacer maintains a sealed cavity that can be filled with air or inert gases like argon or krypton. This design reduces heat transfer between interior and exterior environments, significantly improving energy efficiency.

The role of the spacer is to:

- Maintain a consistent gap between glass panes

- Ensure airtightness and structural integrity

- Minimize thermal bridging at the glass edge

For an overview of how IGUs impact energy performance, see Insulating Glazing Unit: Energy Efficiency and Savings.

Why Spacers Matter in IGUs

Spacers directly influence several critical performance metrics:

- Thermal Conductivity: The spacer material determines how much heat escapes through the edge of the glass unit. Lower conductivity means higher thermal performance.

- Condensation Resistance: High-performance spacers reduce cold spots at glass edges, preventing condensation.

- Durability: Strong, resilient spacers enhance the structural stability and longevity of the IGU.

- Production Efficiency: Advanced spacer technologies simplify the manufacturing process and allow for more consistent quality.

For insights into moisture performance, check out Insulating Glazing Unit: Reducing Condensation and Moisture.

Types of Insulating Glazing Unit Spacers

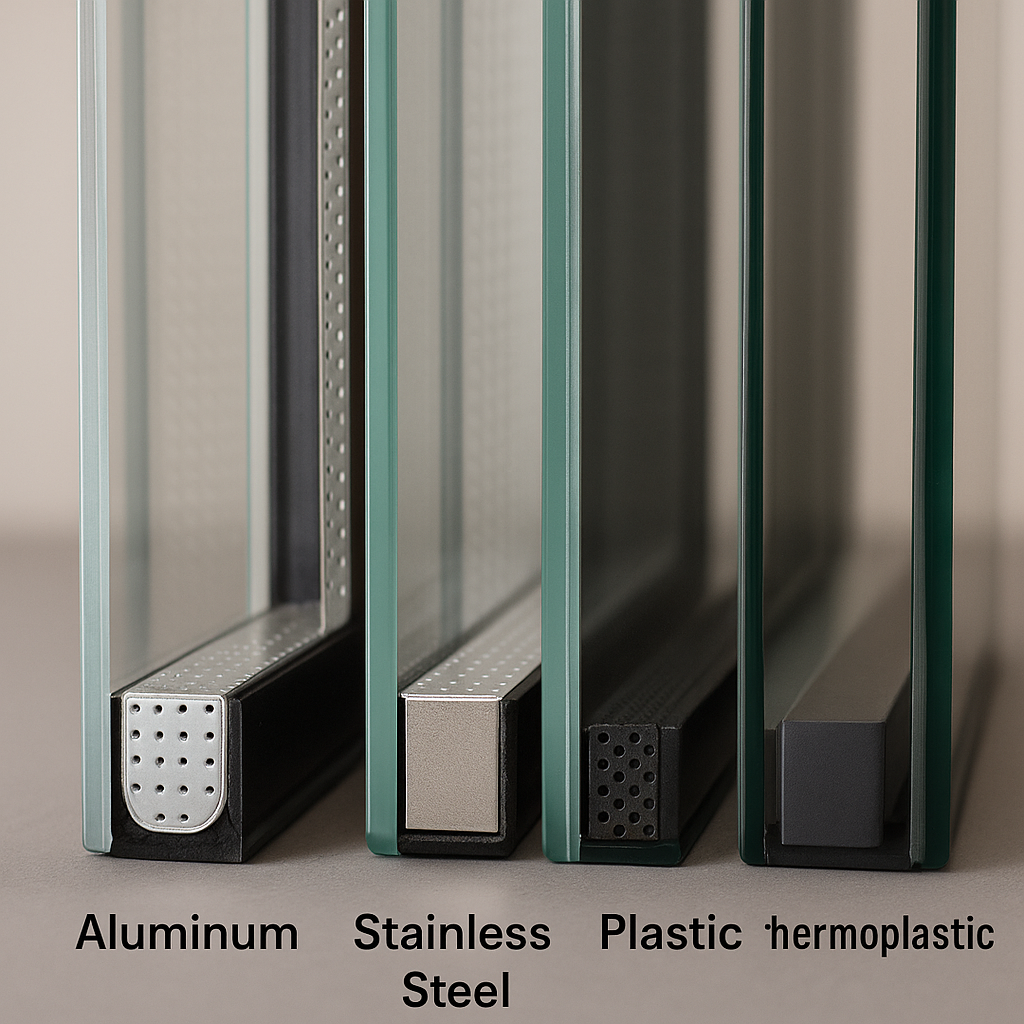

Spacers are available in a variety of materials and configurations, each with its own advantages and drawbacks. The main categories include:

1. Aluminum Spacers

Traditionally the most commonly used, aluminum spacers are:

- Structurally strong

- Easy to process

- Cost-effective

However, aluminum is a highly conductive metal, which leads to significant heat transfer and increased risk of edge condensation. This limits its effectiveness in modern energy-efficient window systems.

2. Warm Edge Spacers

Developed in response to higher energy standards, warm edge spacers are made from materials with lower thermal conductivity. These significantly reduce heat loss and improve condensation resistance.

Common types of warm edge spacers:

- Stainless Steel: Strong like aluminum but with 1/10th the thermal conductivity. Offers a good balance between performance and durability, though not as efficient as polymer-based spacers.

- Plastic-Metal Hybrids: Combine plastics like polypropylene or polycarbonate with thin metal shims. These deliver excellent insulation with sufficient structural strength.

- Flexible Thermoplastics: Use silicone-based or butyl-based materials with integrated molecular sieves. These systems offer unmatched insulation and flexibility for advanced glazing setups.

TPS® Technology: A Modern Spacer Breakthrough

TPS® (Thermo Plastic Spacer) technology has been a game-changer since its launch in 1994. Unlike traditional spacer bars, TPS is applied as a continuous, homogenous bead that includes desiccants, adhesives, and insulation in one step.

Benefits of TPS®:

- Seamless application with no bending or corner joins

- Excellent vapor and gas barrier

- Superior resilience and moisture resistance

- Greater production efficiency

- Longer lifespan

This spacer technology is particularly well-suited for energy-efficient and large-format IGUs, including JUMBO MULTI’ARRISSER applications.

Spacer Thickness and Color: More Than Just Aesthetics

Spacer thickness directly impacts the cavity width between the panes. Wider cavities typically improve insulation, especially when filled with gas. However, thicker spacers must be balanced with structural integrity and overall window depth.

Color also matters:

- Silver or grey: Traditional metallic look

- Black or bronze: Reduces glare and creates a modern aesthetic

Though primarily a design consideration, darker colors may also improve solar gain control by absorbing more light at the edges.

The Role of Sealants

Spacers are bonded to the glass using sealants, which ensure airtightness and structural performance. A high-quality IGU uses a dual-seal system:

- Primary Seal (Butyl): Prevents gas leakage

- Secondary Seal (Silicone, Polyurethane, or Polysulphide): Provides structural bonding and UV/moisture resistance

Poor sealing can result in gas loss, moisture ingress, and ultimately IGU failure.

Installation Tools and Spacer Integrity

Spacer performance also depends on proper handling and installation. Specialized tools help maintain spacer alignment and prevent deformation:

- Lifting clamps: For safe transport and positioning of glass panels

- Suction cup: For smooth, damage-free installation on sensitive glass surfaces

Spacer Selection Based on Climate and Application

The best spacer choice depends on the building’s climate zone and functional requirements:

- Cold climates: Favor TPS or hybrid spacers for maximum insulation

- Humid environments: Prioritize condensation resistance (e.g., stainless steel or thermoplastics)

- Commercial projects: May need high-strength options like hybrid or stainless steel spacers

- Eco-friendly buildings: Should align with sustainability goals by using long-lasting, thermally efficient materials

Sustainability and Environmental Impact

High-performance spacers contribute to:

- Reduced energy consumption

- Lower greenhouse gas emissions

- Extended IGU service life

Combining effective spacers with green design strategies, like those outlined in Bright View Landscape with Green Waste Reduction Tips, can greatly enhance a building’s environmental footprint.

Conclusion: Why Spacer Choice Matters

The insulating glazing unit is only as good as its components, and the spacer is no exception. Choosing the right spacer technology impacts:

- Thermal insulation

- Condensation resistance

- Durability and service life

- Manufacturing efficiency

Whether you’re aiming for passive house standards, retrofitting heritage properties, or simply upgrading windows for better comfort, understanding spacer options is essential.

Explore more IGU benefits in Insulating Glazing Unit | Thermal Insulation Benefits, and make the smart choice for long-term performance and sustainability.