Float glass is one of the most widely used glass products in modern construction and manufacturing. From windows and doors to mirrors and automotive glass, float glass provides a versatile, flat, and distortion-free material that serves multiple industries. Its production involves a sophisticated process, combining advanced technology and precise engineering.

This article dives into the world of float glass manufacture, shedding light on the production processes, major global players like Emirates Float Glass and Mediterranean Float Glass, and its applications—from glass plate fabrication to glass installation in homes and skyscrapers.

What Is Float Glass?

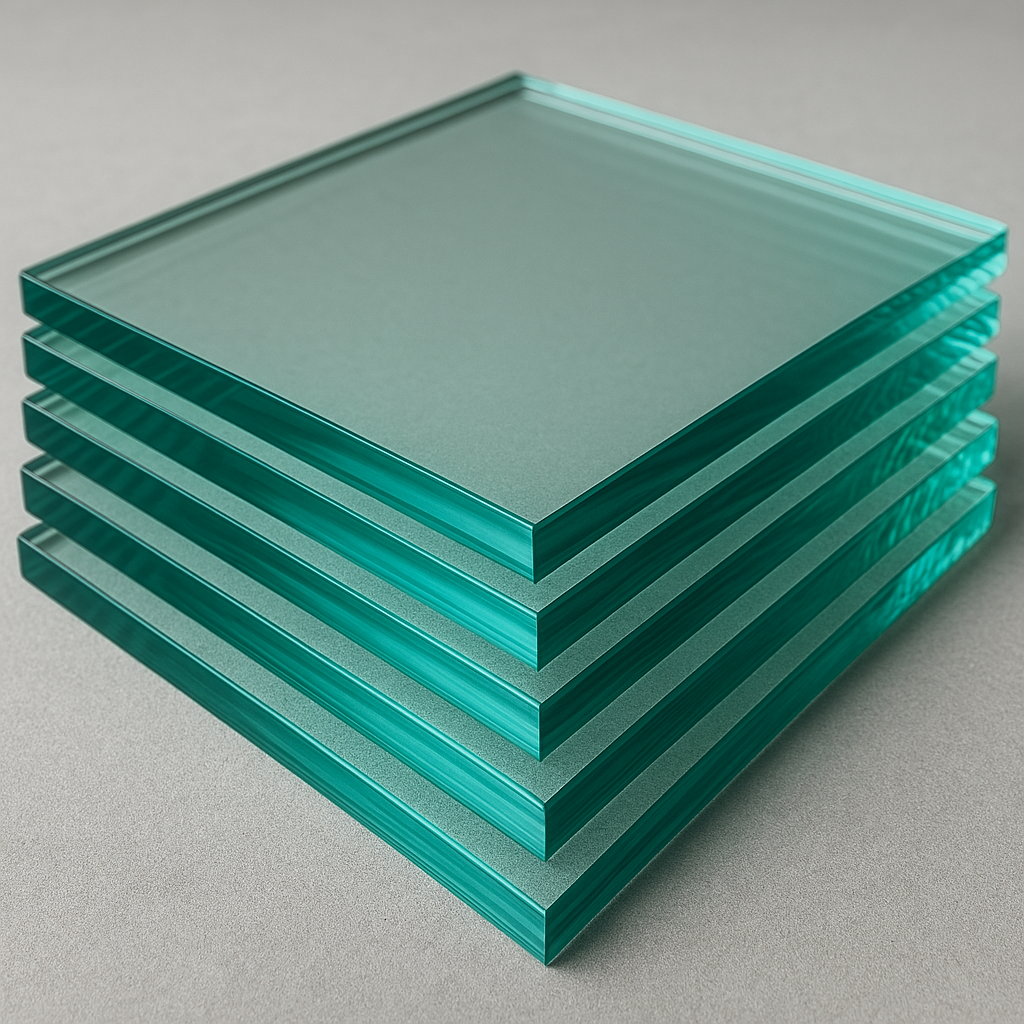

Float glass is a type of flat glass produced by floating molten glass on a bed of molten tin. This method creates glass with uniform thickness, smooth surfaces, and excellent optical clarity.

Characteristics of Float Glass

- Uniform thickness and flatness

- High optical quality

- Ease of cutting and shaping

- Compatibility with coatings and treatments

- Used in a wide range of industries

Float glass is the foundational product for many other types of processed glass, such as laminated, tempered, or insulated glass.

The Float Glass Manufacturing Process

Float glass production is a continuous, precision-controlled process that takes place in large-scale industrial facilities. Let’s break it down into key stages:

1. Raw Material Preparation

The process starts by mixing raw materials:

- Silica sand

- Soda ash

- Limestone

- Dolomite

- Recycled glass (cullet)

These materials are measured and blended to form a batch.

2. Melting in the Furnace

The mixed batch is fed into a furnace and heated to around 1,500°C (2,732°F) until it becomes a molten glass mixture. The melting process is continuous and carefully monitored for impurities.

3. Float Bath Formation

The molten glass flows onto a bath of molten tin in a sealed chamber. Since glass is lighter than tin, it floats and spreads evenly, forming a flat ribbon with parallel surfaces.

4. Annealing

As the ribbon of glass exits the float bath, it enters the annealing lehr—a long, temperature-controlled tunnel. Here, the glass is gradually cooled to reduce internal stresses, which ensures structural integrity and reduces the risk of breakage.

5. Cutting and Inspection

After cooling, the glass is cut into standard or custom sizes. High-speed automated systems inspect for defects, and any substandard sheets are recycled into the batch for reprocessing.

Applications of Float Glass

Float glass is incredibly versatile and serves a wide range of functions in both residential and commercial sectors.

Common Uses of Float Glass

- Windows and doors in homes and office buildings

- Glass curtain walls for modern skyscrapers

- Mirrors after silvering and polishing

- Automotive glass

- Solar panels and greenhouse panels

- Furniture and shelving

- Interior partitions and shower enclosures

In all these applications, float glass is often a key component of the final glass installation process, whether it’s being used for external facades or elegant interiors.

Key Players in the Global Float Glass Industry

The float glass industry is dominated by several global manufacturers known for innovation, quality, and large-scale production capabilities. Below are some of the most influential players:

Emirates Float Glass

Emirates Float Glass (EFG), based in Abu Dhabi, UAE, is a major player in the Middle East. Operating one of the largest float glass facilities in the region, EFG produces high-quality glass for architectural and automotive use.

Key facts:

- Daily capacity exceeding 600 tons

- Exports to over 60 countries

- Focus on sustainability and energy-efficient glass

Mediterranean Float Glass

Located in Algeria, Mediterranean Float Glass (MFG) is North Africa’s leading float glass producer. MFG provides float glass solutions across Africa and Europe, emphasizing quality and technological advancement.

Highlights:

- Advanced float line with strict quality control

- Strong presence in European markets

- Wide range of glass thicknesses and dimensions

Other Major Float Glass Manufacturers

- Saint-Gobain (France): One of the oldest and most diversified float glass producers.

- NSG Group / Pilkington (Japan/UK): Renowned for their innovations in architectural and automotive glass.

- Guardian Glass (USA): Major global supplier with float plants across continents.

- AGC Glass (Japan): Produces float glass for construction, automotive, and high-tech applications.

These companies help shape the float glass landscape by constantly improving processes, investing in research, and meeting the growing demand for sustainable solutions.

Innovations in Float Glass Industries

The float glass industries are evolving rapidly due to increasing demand for energy-efficient, sustainable, and smart glass solutions.

Recent Developments in Float Glass Manufacture

- Low-E coatings: Improve energy efficiency by reducing heat transfer.

- Smart glass integration: Switchable glass that adjusts transparency.

- Recycled content: Manufacturers are increasing the use of cullet to lower emissions.

- Automated quality control: Real-time defect detection through AI and machine vision.

These innovations ensure float glass remains at the forefront of modern building technologies and product design.

Challenges in Float Glass Production

While float glass is widely used, the manufacturing process has its challenges:

- Energy consumption: High temperatures demand significant energy, increasing carbon footprint.

- Raw material costs: Fluctuations in the cost of sand, soda ash, and additives affect pricing.

- Environmental regulations: Producers must adapt to stricter environmental standards.

Manufacturers must continually innovate and invest in eco-friendly practices to remain competitive and sustainable.

Sustainability in Float Glass Manufacture

Many float glass manufacturers are adopting greener methods to reduce their environmental impact.

Sustainability Strategies

- Waste heat recovery systems

- Solar-powered manufacturing facilities

- Water recycling processes

- Low-emission glass products

Companies like Emirates Float Glass and Mediterranean Float Glass are leading the way by integrating sustainability into every stage of production.

Float Glass and the Future of Glass Installation

As construction trends shift toward transparency, natural light, and energy efficiency, float glass remains central to architectural design. From skyscrapers to minimalist homes, the ability to install large, flawless glass panels depends on innovations in float glass manufacture.

The success of modern glass installation depends on high-quality float glass. Whether used in structural facades or elegant partitions, the foundation begins at the float glass plant.

Conclusion: The Global Reach and Future of Float Glass

Float glass is an essential building block of modern life. From elegant glass plate applications to large-scale glass installation in commercial architecture, its role is undeniable. Thanks to major players like Emirates Float Glass, Mediterranean Float Glass, and other global float glass industries, this material continues to evolve, becoming more efficient, sustainable, and versatile.

As new technologies and eco-friendly practices shape the industry, float glass will remain at the heart of innovation—supporting everything from energy-efficient buildings to futuristic smart homes. Whether you’re an architect, contractor, or designer, understanding the process and players behind float glass can inspire better, more sustainable design choices.