PVB laminated glass is a critical material in modern safety, architectural, and design applications. Known for its strength, clarity, and ability to remain intact upon impact, it is widely used in everything from high-rise facades to vehicle windshields. This article breaks down how PVB laminated glass is made, the processes involved, and why this type of laminated glass has become so integral to the construction and design industries. We’ll also explore how it compares to alternatives like SGP laminated glass, how to handle its installation and care, and what influences the final price of PVB laminated glass.

Understanding PVB Laminated Glass

Before delving into the manufacturing process, it’s essential to clarify what PVB laminated glass actually is. Laminated glass consists of two or more layers of glass bonded with an interlayer—typically PVB (polyvinyl butyral). This interlayer is what makes the glass strong, resilient, and safe, even when broken. When laminated glass breaks, the interlayer holds the shards in place, preventing injury and maintaining the structural integrity of the panel.

PVB laminated glass is widely chosen due to its excellent adhesion to glass, acoustic insulation, optical clarity, and resistance to UV rays. To explore its broad capabilities and applications, refer to PVB Laminated Glass: Everything You Need to Know.

The Manufacturing Process of PVB Laminated Glass

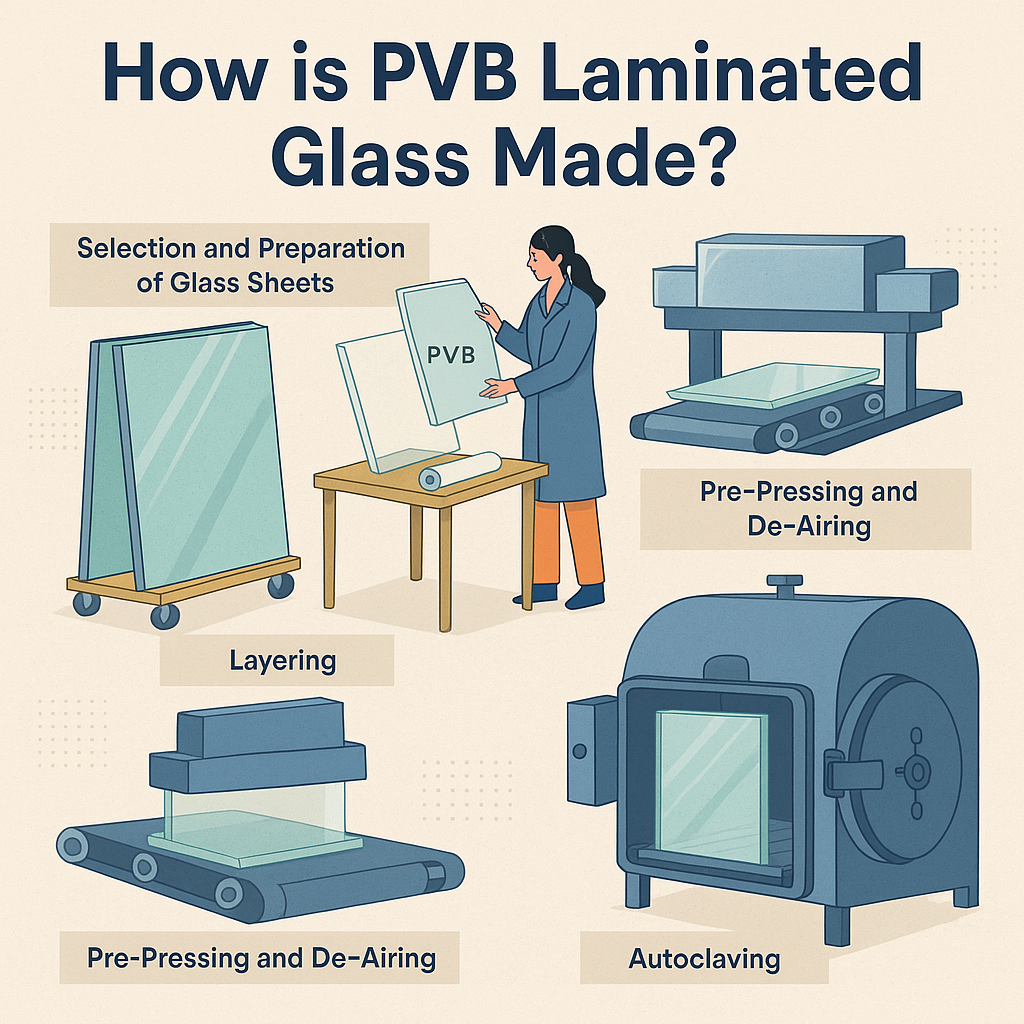

The process of creating PVB laminated glass involves several controlled stages to ensure the final product meets rigorous quality and safety standards. Below is a detailed look at each step.

1. Selection and Preparation of Glass Sheets

The process begins by selecting high-quality float glass. Depending on the application, this glass may be annealed, heat-strengthened, or tempered. Each sheet is cleaned meticulously to remove any dust, oil, or microscopic particles. Any imperfection can lead to poor adhesion or optical defects in the final laminated panel.

For certain applications like safety glazing or soundproofing, special coatings (e.g., low-E coatings) may also be applied to the glass before lamination.

2. Cutting and Edge Processing

Once the glass is selected, it is cut to size using precision CNC glass-cutting tables. Edges are then polished or beveled to reduce sharpness, prevent stress fractures, and ensure a better seal during lamination. Proper edge work is also crucial for long-term durability, especially in outdoor or load-bearing installations.

3. PVB Interlayer Preparation

The PVB interlayer is a resin-based film that is typically stored in cool, humidity-controlled environments to prevent it from becoming sticky or degrading. Rolls of PVB are cut to size to match the dimensions of the glass. The interlayer comes in a variety of thicknesses (commonly 0.38 mm, 0.76 mm, or more), depending on the safety or acoustic requirements.

4. Layering Process

The cleaned glass sheets are brought into a cleanroom where the PVB film is placed between them. This sandwich structure is manually aligned and assembled, then pressed together lightly. To minimize contamination and ensure perfect alignment, this step is often performed in a dust-free environment with strict quality control.

5. Pre-Pressing and De-Airing

After layering, the glass sandwich is passed through a pre-pressing section, usually consisting of heated rollers. This stage removes most of the air trapped between the layers. The goal is to create partial bonding and prepare the assembly for the next stage.

De-airing is a critical step. Even microscopic air bubbles can cause delamination, optical haze, or a weak bond. This step can be done with vacuum bagging or vacuum ring techniques for more precise results.

6. Autoclaving

Once the glass layers are pre-bonded, they enter an autoclave chamber. This high-pressure oven exposes the laminated stack to temperatures around 130–150°C and pressures of 10–15 bars for about 30 to 60 minutes. This intense heat and pressure bond the glass and PVB interlayer at a molecular level.

The result is a strong, clear, durable laminated glass panel ready for architectural or commercial use.

Quality Control and Inspection

Each PVB laminated glass panel is subjected to a series of tests to confirm optical clarity, adhesion strength, impact resistance, and compliance with safety standards. Defective products are discarded or recycled. The finished product is then cleaned again, packaged securely, and labeled with batch and specification details for traceability.

PVB Laminated Glass in Architecture and Design

Thanks to its excellent safety and design characteristics, PVB laminated glass has become indispensable in modern architectural projects. It is commonly used in:

- Skylights and overhead glazing

- Curtain walls and facades

- Balcony railings and staircases

- Floor panels and bridges

- Acoustic glass partitions

Architects appreciate PVB laminated glass not just for its safety, but for its ability to incorporate tints, patterns, and digital prints without compromising structural performance. It allows for creativity and transparency while meeting safety codes.

PVB Laminated Glass Installation Considerations

Proper PVB laminated glass installation is essential to maximize durability and performance. Some key guidelines include:

- Using compatible sealants to avoid chemical reactions with the interlayer

- Ensuring appropriate drainage systems to prevent water intrusion

- Handling glass with suction cups or padded frames to avoid edge damage

- Verifying structural support systems are adequate for glass weight

Professionals trained in laminated glass installation should always be engaged for structural or exposed-edge applications.

PVB Laminated Glass Care and Maintenance

Once installed, PVB laminated glass requires routine maintenance to retain its clarity and strength. Here are a few care recommendations:

- Use soft, lint-free cloths and pH-neutral cleaners for cleaning

- Avoid harsh solvents like ammonia or strong acids that may degrade the PVB layer

- Regularly inspect edges for signs of delamination or moisture intrusion

- Clean drainage systems and weep holes periodically

Compared to other safety glazing options, PVB laminated glass is relatively low-maintenance, especially when properly installed and protected from direct moisture exposure.

Comparing PVB Laminated Glass and SGP Laminated Glass

While PVB laminated glass meets the needs of most applications, some demanding environments require more advanced interlayers like SGP (SentryGlas Plus). SGP offers greater stiffness, durability, and resistance to edge creep. It’s ideal for hurricane zones, high-load installations, and ultra-clear structural glass.

However, PVB laminated glass remains the more cost-effective and versatile option for everyday architectural needs.

PVB Laminated Glass Price Factors

The price of PVB laminated glass depends on several variables:

- Thickness of glass and interlayer

- Number of layers (e.g., double or triple lamination)

- Special treatments (acoustic, colored, printed)

- Size and shape (custom geometries add cost)

- Quantity ordered and regional availability

On average, PVB laminated glass ranges from $20–$60 per square foot. Bulk pricing and supplier relationships can influence this range significantly. Installation costs and framing systems are additional expenditures to consider.

Top PVB Laminated Glass Manufacturers

Leading PVB laminated glass manufacturers offer consistent quality, supply reliability, and customization. When sourcing glass, it’s important to choose suppliers that meet ISO, EN, or ASTM standards and offer proof of durability testing.

Some manufacturers also produce their own PVB interlayers, offering greater integration and quality control.

Conclusion: Why Understanding PVB Laminated Glass Production Matters

Knowing how PVB laminated glass is made provides deeper insight into its structural integrity, performance, and potential. It’s not just glass with a plastic sheet—it’s a multi-layered safety solution engineered for strength, clarity, and beauty. Whether you’re planning a commercial high-rise or a custom home, understanding the process ensures better decision-making in design, installation, and long-term care.

The transparency of its manufacturing, combined with a strong track record of safety and performance, makes PVB laminated glass a trusted choice across industries. For more details on its applications, benefits, and buying tips, revisit PVB Laminated Glass: Everything You Need to Know.