Before digital sensors and film revolutionized modern imaging, glass plate photography defined an era of precision and artistic expression. While this historic medium is now largely relegated to museums and archives, its influence continues in surprising ways—especially in the world of float glass. The emphasis on clarity, surface quality, and stability in early photographic glass plates directly shaped the technologies and standards that define today’s glass manufacturing.

In this article, we explore the origins and impact of glass plate photography, its connection to contemporary float glass manufacture, and how the legacy of glass-based imaging remains embedded in industries like Emirates Float Glass and Mediterranean float glass production.

Understanding Glass Plate Photography

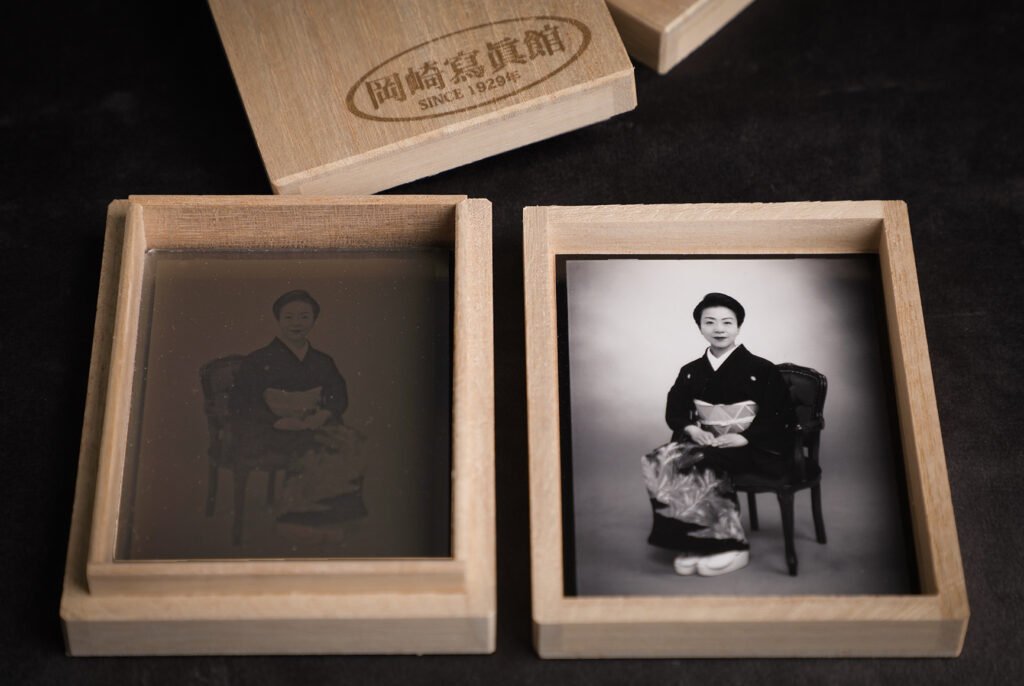

Glass plate photography refers to a photographic process in which images are captured on glass surfaces coated with a light-sensitive emulsion. This method became the dominant form of photography from the 1850s through the early 20th century.

There are two primary types of glass plates used:

- Wet plate collodion negatives (1850s–1880s): Required the plate to be exposed and developed while still wet, resulting in high-resolution and detailed images.

- Dry plate negatives (1880s–1920s): Employed a gelatin emulsion, allowing plates to be prepared in advance and developed later, greatly improving convenience and usability.

Photographers prized glass plates for their:

- Exceptional sharpness

- Flat, stable recording surface

- Durability compared to early paper-based alternatives

These properties made glass plate photography a crucial tool for artists, scientists, explorers, and early journalists.

The Material Foundations: Glass for Photography

Glass used in photography needed to meet strict criteria:

- Optical clarity

- Uniform thickness

- No warping or surface distortion

- Chemical resistance for emulsion application

This high standard required glass manufacturers to innovate processes that would later become foundational in float glass manufacture. The pursuit of near-perfect flatness and clarity in photographic glass directly influenced the development of better glass-melting techniques, polishing systems, and quality control measures.

From Photographic Plates to Float Glass Technology

The legacy of glass plate photography set the stage for one of the most transformative developments in the glass industry: the invention of float glass in the mid-20th century.

In 1952, Sir Alastair Pilkington developed the float glass process, which involves floating molten glass over a bath of molten tin. This method produces glass that is:

- Perfectly flat

- Free of surface imperfections

- Cost-effective to produce at scale

- Consistent in thickness

These attributes, originally sought after in photographic plates, are now standard in clear float glass used in modern construction, automotive, solar, and electronics applications.

The Role of Glass Plate Photography in Today’s Float Glass Industries

While the use of glass plates in photography has largely faded, their influence can still be seen in global float glass industries. Two regions where this legacy is particularly evident are the UAE and the Mediterranean.

Emirates Float Glass

Emirates Float Glass (EFG), based in Abu Dhabi, is one of the most advanced float glass producers in the Middle East. EFG continues the tradition of excellence in glass clarity and uniformity—qualities that were first demanded by glass plate photography more than a century ago.

EFG manufactures:

- Clear float glass for windows and façades

- Solar control glass for energy efficiency

- Reflective and tinted glass for architectural aesthetics

These products benefit from high-tech production methods that can be traced back to the pursuit of flawless photographic glass.

Mediterranean Float Glass

In the Mediterranean region, manufacturers like Şişecam (Turkey), Guardian Glass (Spain), and Saint-Gobain (Italy and France) lead the way in high-quality float glass manufacture.

These companies focus on:

- Low-iron float glass with ultra-high clarity

- Laminated and tempered products for safety and durability

- Decorative and insulated glass units

The emphasis on visual quality and consistency continues the tradition set by early glass plate negatives, which required the best glass to produce high-fidelity images.

Preserving the Legacy of Glass Plate Photography

As we celebrate technological advances in float glass industries, it’s worth remembering the artistic and scientific contributions made possible by glass plate photography.

Archival Projects

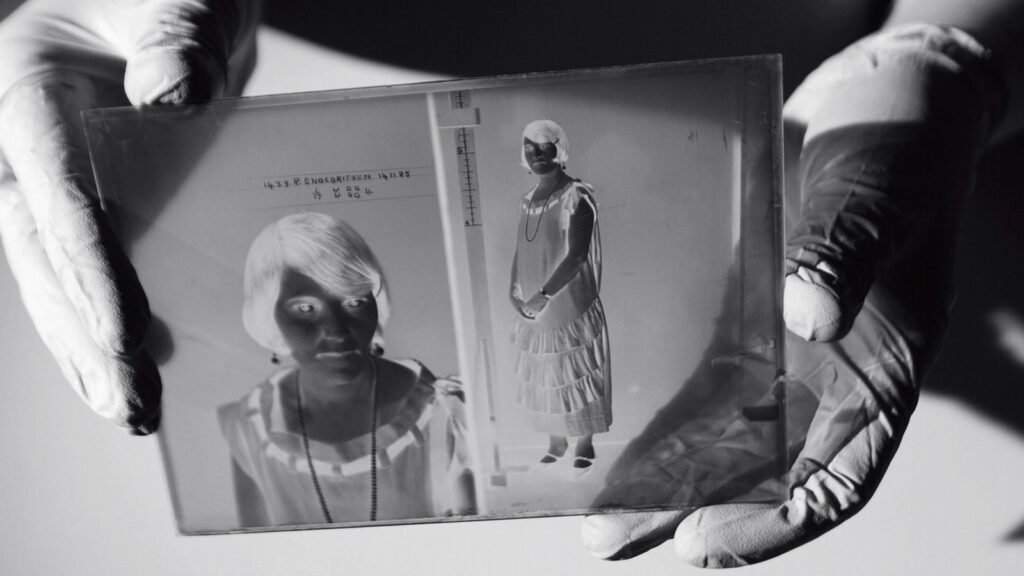

Museums, universities, and historical societies are digitizing vast collections of glass plate negatives, which capture:

- Architectural landmarks from the 1800s

- Early scientific observations

- Cultural moments from pre-digital history

Preserving these images allows modern viewers to experience photography’s early artistry and technical mastery. Many of these archived plates are now housed in institutions across the UAE and the Mediterranean.

Explore how historical glass plate negatives continue to inform industrial innovation and cultural preservation.

Artistic Revival

Contemporary photographers and artists are rediscovering glass plate photography for its unique aesthetic and hands-on technique. By reviving wet plate and dry plate methods, today’s creatives connect the past with modern expression.

This artistic movement honors the craftsmanship that originally drove improvements in glass production—ultimately leading to the rise of clear float glass.

Applications of Float Glass in the Modern Era

Thanks to the evolution driven in part by photographic glass, float glass is now used in:

- Commercial architecture: Curtain walls, canopies, skylights

- Residential buildings: Energy-efficient windows, balustrades, shower enclosures

- Automotive: Windshields, sunroofs, side windows

- Solar energy: High-transparency glass for photovoltaic panels

- Interior design: Mirrors, partitions, furniture

These applications demand the same attributes as historical photographic glass—clarity, strength, and precision.

The Technological Bridge: How Photography Led to Modern Glassmaking

Here’s how innovations in photography contributed to float glass development:

| Glass Plate Photography | Impact on Float Glass |

|---|---|

| Need for optical clarity | Led to purer raw material blends |

| Requirement for flatness | Inspired precision forming techniques |

| Chemical emulsion resistance | Advanced surface treatment processes |

| Demand for consistency | Fostered automation in production |

This bridge between artistic necessity and industrial advancement underscores how past technologies remain deeply connected to current innovations.

Conclusion

Glass plate photography was more than an artistic or scientific medium—it was a catalyst for innovation in the glass industry. The same demands that made photographic plates so effective—clarity, consistency, and durability—laid the foundation for the float glass manufacture techniques we rely on today.

From the historic negatives still preserved in archives to the ultra-modern glass panels installed in skyscrapers, the legacy lives on. Whether you’re examining the heritage of glass plate negatives or exploring cutting-edge float glass production in the UAE or the Mediterranean, the connection between past and present is clear—literally and figuratively.

Understanding this lineage enriches our appreciation for the glass that surrounds us every day, reminding us that innovation often begins with art.