Installing laminated glass windows requires attention to detail, proper tools, and adherence to safety standards. Whether you’re working on a residential renovation or a large-scale architectural project, laminated glass offers unmatched benefits in security, soundproofing, and energy efficiency.

In this guide, we cover everything from preparation to sealing and maintenance. You’ll also learn why laminated glass is ideal for modern window installations and where to source the best materials for your project.

What Is Laminated Glass and Why Use It in Windows?

Laminated glass is made by bonding two or more panes of glass together with an interlayer, typically PVB (polyvinyl butyral), EVA (ethylene vinyl acetate), or SGP (ionoplast). This interlayer holds the glass in place when shattered, providing superior safety, UV protection, and sound insulation.

In window applications, laminated glass is increasingly preferred due to:

- Resistance to break-ins and forced entry

- Noise control for urban or high-traffic areas

- UV filtering that protects interior furnishings

- Compliance with modern building codes

- Enhanced storm and impact resistance in coastal zones

When properly installed, laminated glass improves indoor comfort and long-term building performance.

Tools and Materials Needed for Laminated Glass Installation

Before beginning, gather the following:

Tools

- Glazing knife

- Putty scraper

- Caulking gun

- Level

- Suction lifters (for safe glass handling)

- Measuring tape

- Safety gloves and goggles

- Drill and bits (for fixing or frame adjustment)

Materials

- Laminated glass panes (cut to size)

- Window frames (aluminum, uPVC, wood)

- Setting blocks

- Neutral cure silicone sealant

- Backer rod (for spacing/sealing)

- Glazing tape (if required)

- Shims or spacers

For high-quality panes, check trusted vendors like:

🔗 Where to Buy Laminated Glass Sheets

Step-by-Step Installation Process

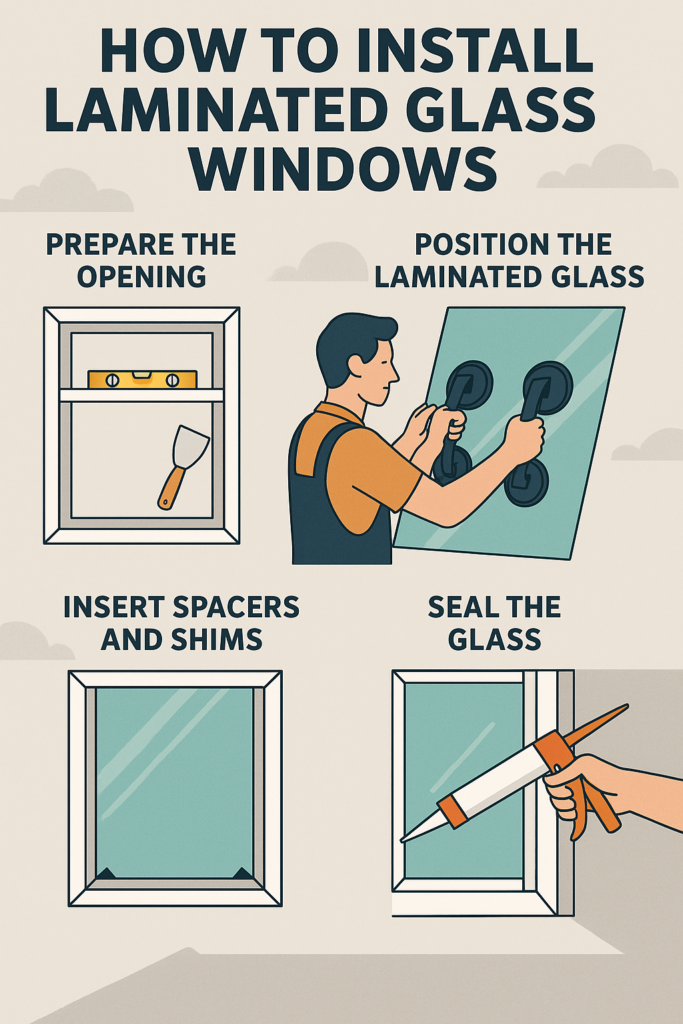

1. Prepare the Opening

Ensure the window opening is level and free of debris or dust. If you’re replacing an old window, remove the previous glazing and clean the frame surface thoroughly.

2. Check Glass Dimensions and Orientation

Laminated glass has specific structural properties and may include directional films (e.g., UV-filtering or acoustic layers). Verify:

- Glass size against the frame opening

- Label direction (some interlayers are directional)

- Clean surface and edge quality

3. Insert Setting Blocks

Setting blocks are placed at the bottom of the frame to:

- Distribute weight evenly

- Prevent glass-to-frame contact

- Allow water drainage if installed in external glazing

Blocks should be positioned about 1/4 of the glass width in from each edge.

4. Position the Laminated Glass

Using suction cups and two-person handling:

- Tilt the glass into the opening

- Rest it on the setting blocks

- Center the pane, maintaining a 3mm to 5mm gap on all sides for expansion

If the frame has pre-installed gaskets or clips, make sure the glass fits securely without forcing.

5. Apply Spacers and Shims

Use shims to maintain even gaps and ensure the pane stays aligned. Avoid metal shims that could corrode or damage the interlayer. This is critical for large windows or external glazing systems.

6. Seal the Glass

Use neutral cure silicone sealant (non-acidic) to seal around the perimeter:

- Insert backer rod into the gap

- Apply sealant evenly on all sides

- Smooth with a putty knife or sealant tool

- Allow proper curing time (typically 24–48 hours)

Good sealing prevents air and water infiltration, enhancing thermal performance.

7. Inspect and Clean

After installation:

- Inspect sealant for voids or bubbles

- Test the pane’s stability by gently applying pressure

- Clean the surface with a non-abrasive glass cleaner

Proper cleaning and maintenance will protect the interlayer and glass clarity.

Laminated Glass Installation Tips and Best Practices

- Always use edge-polished laminated glass to prevent chipping during installation

- Avoid using acidic silicone that can damage PVB interlayers

- Keep laminated glass dry and avoid direct contact with cement or plaster

- Use low-E laminated glass in sunny locations for energy savings

- Consider acoustic laminated glass for bedrooms or conference rooms

Common Applications of Laminated Glass Windows

1. Residential Windows

From noise reduction to safety, laminated windows enhance comfort and peace of mind.

2. Office and Commercial Glazing

Ideal for exterior facades, storefronts, and interior partitions.

3. High-Rise and Coastal Buildings

Wind resistance and UV protection make laminated glass ideal for curtain walls and high-elevation glazing.

4. Soundproof Rooms and Studios

Specialized acoustic interlayers reduce decibel levels significantly.

Explore this option:

🔗 Laminated Glass to Prevent Lighting Issues Indoors

Laminated Glass Maintenance After Installation

Proper laminated glass care extends the lifespan and performance of your windows.

- Clean regularly with a soft cloth and neutral glass cleaner

- Inspect seals yearly for shrinkage or cracking

- Avoid harsh chemicals like ammonia or abrasives

- Keep water from pooling at the base (especially in exterior windows)

Laminated glass maintenance is simple but crucial—neglecting it may lead to interlayer delamination or hazing over time.

What Is the Price of Laminated Glass for Windows?

Factors That Affect Price:

- Glass thickness (6.38mm, 8.76mm, 13.52mm, etc.)

- Interlayer type (clear, acoustic, UV-filtering)

- Pane size and shape

- Edge treatment and custom finishes

Price Range:

| Glass Type | Cost per m² (USD) |

|---|---|

| Standard Clear (6.38mm) | $35–$55 |

| Tinted or Acoustic Laminated | $55–$90 |

| SGP Structural Laminated | $100–$180+ |

| Decorative Printed Laminated | $80–$150+ |

Installation costs may add $20–$50 per m² depending on location and labor availability.

Conclusion

Installing laminated glass windows enhances building safety, acoustic control, and energy efficiency. Whether you’re handling the project yourself or working with a contractor, following the proper techniques ensures long-term performance and visual appeal.

By sourcing from trusted laminated glass manufacturers, using the correct tools, and sealing effectively, you can create windows that are both beautiful and durable.

Ready to start sourcing your panels?

🔗 Where to Buy Laminated Glass Sheets

🔗 Laminated Glass to Prevent Lighting Issues Indoors