When planning a residential or commercial construction project, selecting the right windows and glass solutions is essential for achieving energy efficiency, comfort, and long-term savings. One of the most effective modern solutions is the insulating glazing unit (IGU). IGUs outperform single-pane glass by reducing heat transfer, improving noise insulation, and boosting overall property value.

But what exactly should you consider when buying IGUs for a new project? From materials and design to long-term ROI, this article outlines all the key factors you need to know before making your investment.

What is an Insulating Glazing Unit (IGU)?

An insulating glazing unit is a sealed assembly made up of two or more panes of glass separated by a spacer and often filled with insulating gases like argon or krypton. The panes are sealed at the edges to create an airtight cavity that reduces heat transfer.

This design improves thermal performance, reduces energy costs, and enhances indoor comfort, making IGUs a preferred choice in modern architecture. Depending on the project’s needs, IGUs can be customized with coatings, gas fills, or triple-pane designs to maximize performance.

Key Factors Affecting IGU Prices

When budgeting for IGUs in a new build or renovation project, it’s important to understand what drives their cost.

1. Materials Used

- Glass Type: Standard clear glass is affordable, but options like tempered or laminated glass increase safety and durability at a higher price.

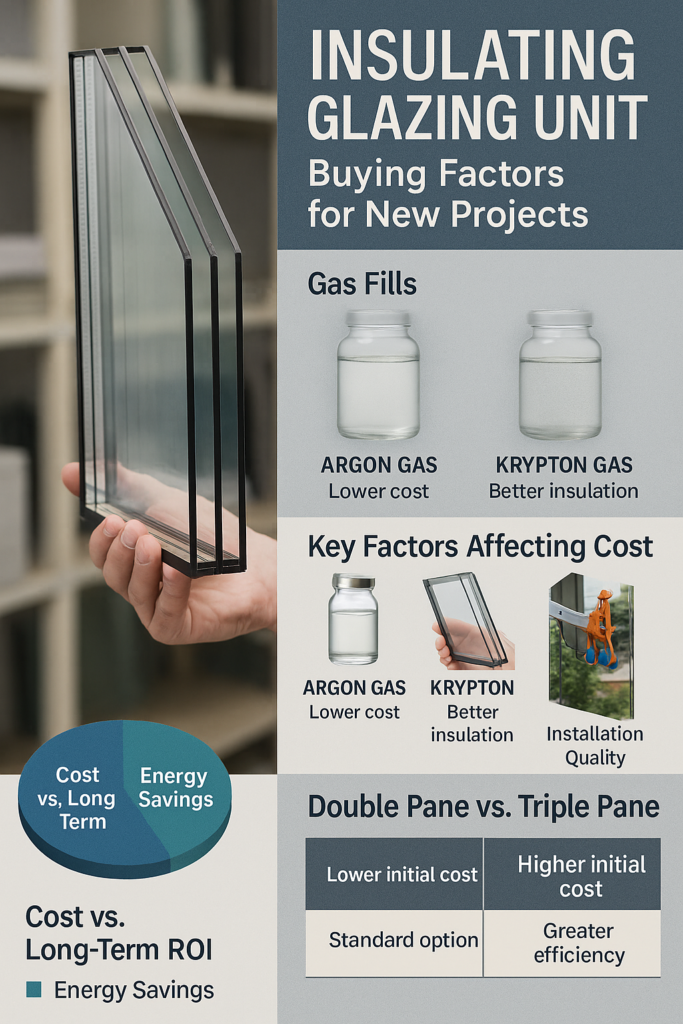

- Gas Fill: Argon is the most common and economical option, while krypton provides superior insulation but is more expensive.

- Spacers: Traditional aluminum spacers are cost-effective but conduct heat, whereas warm-edge foam spacers cost more but improve energy efficiency.

2. Design and Specifications

- Double vs. Triple Pane: Double-pane IGUs are standard and budget-friendly, while triple-pane units provide greater insulation at a higher upfront cost.

- Custom Shapes and Sizes: Unique or oversized windows add to the complexity and price of manufacturing.

- Coatings: Low-emissivity (Low-E) coatings improve energy efficiency but can increase initial expenses.

3. Supplier and Manufacturing Quality

Different suppliers use different materials, machinery, and quality control measures. Reputable suppliers may charge more, but they ensure longevity and warranty support that reduce long-term costs.

How Materials and Design Influence Project Value

The choice of IGU materials and designs directly impacts both project cost and long-term value.

- Low-E Coatings: While increasing upfront costs, these coatings reduce UV and infrared transmission, lowering energy bills and protecting interiors from fading.

- Gas Fills: Argon is affordable and efficient for most climates, while krypton’s higher density makes it ideal for premium triple-pane windows.

- Spacer Technology: Foam or warm-edge spacers minimize condensation and improve insulation, contributing to higher comfort levels.

By combining these options strategically, project managers can balance budget with long-term performance goals.

Is an IGU Worth the Investment?

Absolutely. While IGUs may initially cost more than single-pane or standard double glazing, their long-term return on investment (ROI) is significant.

Benefits That Justify the Cost:

- Energy Savings: Reduced heating and cooling bills can offset initial costs within a few years.

- Enhanced Comfort: Consistent indoor temperatures eliminate drafts and cold spots.

- Noise Reduction: Multi-pane configurations and gas fills provide excellent soundproofing for urban environments. (See: Insulating Glazing Unit | The Complete Guide to Energy-Efficient Windows)

- Increased Property Value: Energy-efficient upgrades like IGUs are highly appealing to eco-conscious buyers.

- Durability: High-quality IGUs can last decades with proper installation and maintenance.

Buying Factors for New Projects

When purchasing IGUs for a new build, consider the following buying factors:

1. Project Location and Climate

Climate plays a huge role in determining whether double-pane or triple-pane IGUs are best. For moderate climates, argon-filled double panes may suffice. In colder or hotter regions, krypton-filled triple panes are worth the added cost.

2. Energy Performance Goals

If meeting strict building code requirements or achieving certifications like Energy Star, you’ll need IGUs with higher R-values and advanced coatings.

3. Design Requirements

Custom window shapes, oversized glazing, or architectural designs with curtain walls require specialized IGU manufacturing and installation.

4. Installation and Handling

Installing IGUs requires precision. Tools like a vacuum lifter or a forklift boom are often used to handle heavy glass units safely and efficiently during construction. Investing in professional installation ensures airtight seals and prevents premature failure.

5. Supplier Reputation and Warranty

Always evaluate supplier warranties, certifications, and customer reviews. Long warranties on seals and gas fills can protect you from costly replacements down the road.

Comparing Costs vs. Long-Term ROI

While IGUs may cost $10–$20 per square foot or more depending on specifications, the long-term ROI makes them a worthwhile investment.

- Short-Term Costs: Higher upfront compared to single-pane or basic double-pane windows.

- Long-Term ROI: Energy savings, comfort, and resale value outweigh the initial cost within 5–10 years. (Explore: Insulating Glazing Unit | Cost Breakdown and ROI Factors)

Environmental and Sustainability Considerations

IGUs also contribute to sustainable building practices by lowering energy use and reducing carbon footprints. Pairing IGUs with sustainable landscaping—such as Bright View Landscape | Sustainable Landscaping for a Greener Future—can further reduce energy consumption by shading windows and controlling solar heat gain naturally.

Expert Guidance: Choosing the Right IGU

Since no two projects are identical, working with a glazing professional ensures the right balance of budget, energy performance, and aesthetics. For deeper insights, you can explore guides such as:

- Insulating Glazing Unit | Choosing the Right IGU Explained

- Insulating Glazing Unit | Manufacturing Process

- Insulating Glazing Unit | Installation Process Best Practices

Conclusion

Buying the right insulating glazing unit for your project is about balancing materials, design, energy efficiency, and installation quality with budget considerations. While IGUs require a larger upfront investment, they deliver outstanding returns in energy savings, comfort, and property value.

By carefully considering factors like gas fills, coatings, pane configurations, and supplier reputation, you can make an informed decision that aligns with both your short-term budget and long-term goals.

For new construction projects aiming at sustainability and cost efficiency, IGUs aren’t just an option—they’re an essential choice.