When it comes to modern building design, insulating glazing units (IGUs) stand out as one of the most effective solutions for improving energy efficiency, indoor comfort, and noise reduction. Whether for residential upgrades or large-scale commercial projects, IGUs provide superior thermal and acoustic performance compared to traditional single-pane windows.

This guide explores what insulating glazing units are, how they work, their benefits, and the key factors to consider when choosing the right IGU for your property.

What Is an Insulating Glazing Unit?

An insulating glazing unit (IGU) is made of two or more panes of glass separated by a spacer and sealed to form a single airtight unit. The cavity between panes is usually filled with insulating gas such as argon or krypton, which reduces heat transfer. This construction creates a strong thermal barrier, helping to keep indoor spaces warmer in winter and cooler in summer.

IGUs are used in both residential and commercial applications because they improve energy performance, minimize condensation, and reduce outside noise—making them a preferred choice for modern window systems.

Key Features of Insulating Glazing Units

1. Thermal Performance and R-Values

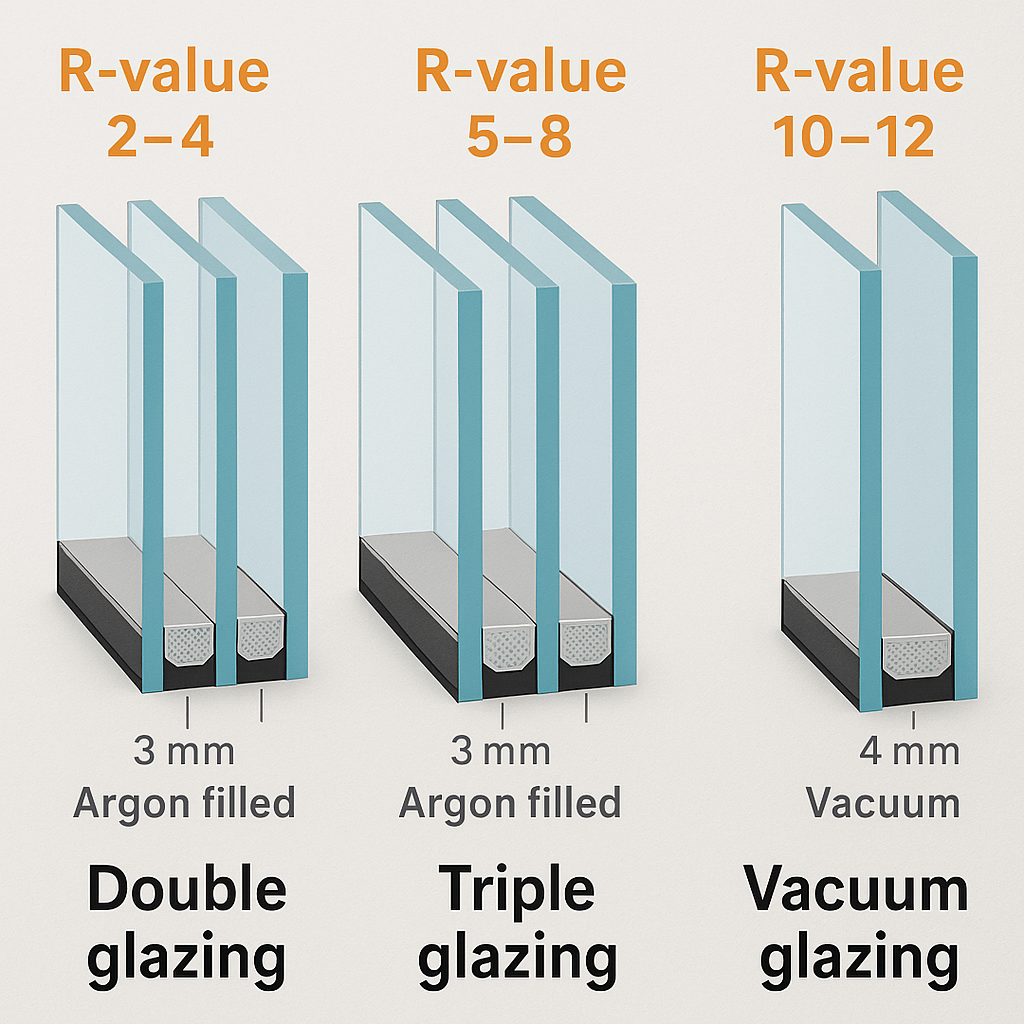

The R-value measures how well a material resists heat flow. Higher R-values mean better insulation.

- Single-Pane Windows: R-value of 0.9–1.1. Least efficient.

- Double-Pane IGUs: R-value of 2–4. Standard for homes and businesses.

- Triple-Pane IGUs: R-value of 5–8. Best for extreme climates.

- Low-E Coatings: Reflect heat while allowing light to pass, further boosting thermal performance.

For a deeper dive into performance values, see Insulating Glazing Unit | Cost Breakdown and ROI Factors.

2. Gas Fills for Enhanced Efficiency

The cavity inside IGUs isn’t just air—it can be filled with special gases:

- Argon Gas: Affordable and effective, ideal for double-pane units.

- Krypton Gas: Denser and more insulating, perfect for triple-pane systems.

- Air: Cheaper but less effective, mostly found in older windows.

Correct gas filling ensures long-term thermal performance, especially when combined with durable sealants.

3. Spacer Materials

Spacers keep the glass panes apart and influence energy efficiency:

- Aluminum Spacers: Strong but highly conductive, reducing efficiency.

- Foam Spacers: Excellent insulation, minimizing condensation risk.

- Stainless Steel Spacers: Balance between durability and insulation.

4. IGU Configurations

- Double-Pane IGUs: Most common, cost-effective, suitable for moderate climates.

- Triple-Pane IGUs: Higher upfront investment but ideal for very hot or cold climates, offering long-term energy savings.

For more insights into assembly methods, review Insulating Glazing Unit | Manufacturing Process.

Benefits of Insulating Glazing Units

1. Energy Efficiency

By reducing heat transfer, IGUs lower energy bills and help buildings meet sustainability standards.

2. Noise Reduction

The multiple layers of glass and insulating gas serve as barriers against external noise, creating quieter indoor spaces. This makes IGUs especially valuable in urban settings or near busy roads.

3. Comfort and Indoor Climate

IGUs minimize drafts, prevent cold spots near windows, and maintain consistent indoor temperatures.

4. Reduced Condensation

IGUs are designed to reduce interior condensation, preserving clarity and extending window life.

Choosing the Right IGU for Your Needs

Climate Considerations

- Moderate climates: Double-pane IGUs with argon gas.

- Extreme climates: Triple-pane IGUs with krypton gas.

Energy Savings and ROI

Although triple glazing has a higher initial cost, it delivers significant long-term energy savings. For ROI insights, see Insulating Glazing Unit | Cost Breakdown and ROI Factors.

Certifications

Look for Energy Star-rated or locally certified products to ensure compliance with efficiency standards.

Professional Guidance

Working with professional installers ensures precise fitting and long-term performance. Learn more in Insulating Glazing Unit | Installation Process Best Practices.

Tools and Equipment in IGU Handling

Handling IGUs requires specialized equipment to ensure safety and efficiency:

- Vacuum lifter: Provides secure lifting of heavy or large glass panes with suction-based gripping.

- Glass lifter: Designed for safe and efficient transport of glass panels in workshops or installation sites.

- Forklift boom: Ideal for extending the reach of forklifts when handling larger IGU crates or heavy units.

Using the right tools prevents damage to the glass while improving workplace safety.

Maintenance and Replacement Considerations

Even the best IGUs have a lifespan. Over time, seals can degrade, leading to fogging or reduced performance.

Signs you may need replacement include:

- Condensation between panes.

- Noticeable drafts or energy bill increases.

- Cracked or damaged seals.

For a complete replacement guide, see Insulating Glazing Unit | Replacement Considerations Guide.

Sustainability Benefits of IGUs

By reducing energy use, IGUs contribute to global sustainability goals. They lower heating and cooling demands, which reduces greenhouse gas emissions.

Pairing IGUs with eco-friendly building practices, such as Bright View Landscape | Sustainable Landscaping for a Greener Future, creates a holistic approach to sustainability in construction and property management.

Conclusion

The insulating glazing unit is a cornerstone of modern window technology, offering unmatched thermal performance, noise reduction, and comfort. From choosing between double and triple-pane systems to selecting the right gas fill and spacer materials, understanding the features of IGUs helps homeowners and businesses make informed decisions.

With proper installation, routine maintenance, and the right equipment like a vacuum lifter or glass lifter, IGUs can deliver decades of reliable performance while reducing energy costs and supporting a greener future.