Energy prices are rising, building codes are tightening, and homeowners expect bright, comfortable rooms without huge power bills. That’s why low emissivity glass has become the default for modern windows and facades.

But once you start specifying glazing, you quickly discover there’s more than one kind of Low-E. The two big families are hard-coat and soft-coat – and they behave quite differently in the real world.

This article unpacks why they’re so different, how each one works, and how to choose the right low emissivity glass for your project.

What Is Low Emissivity Glass?

Low emissivity glass (usually shortened to Low-E glass) is standard float glass that’s been upgraded with a microscopically thin, metal-based coating. This coating:

- Reduces how much heat radiates through the glass

- Reflects long-wave infrared energy (heat)

- Allows high levels of visible light to pass through

“Emissivity” measures how efficiently a surface emits radiant heat. Clear glass has a high emissivity – it absorbs heat and lets it pass through easily. Low-E coatings give the glass a low emissivity, so instead of acting like a warm panel leaking heat, the glass behaves like a selective mirror.

That’s why Low-E glazing is so effective at:

- Cutting winter heat loss and summer heat gain

- Reducing UV damage to interiors

- Improving year-round thermal comfort

For a deeper dive into those benefits, see

How Can Low Emissivity Glass Reduce Heat Loss and UV Damage?

Why Are There Hard-Coat and Soft-Coat Versions?

Low emissivity glass coatings are made in two main ways:

- Hard coat (pyrolytic) – applied while the glass is still red-hot on the float line

- Soft coat (sputtered) – applied later in a vacuum chamber to already-formed glass

The manufacturing method changes:

- How tough the coating is

- How well it insulates

- How clear the glass looks

- Where and how it can be used

Let’s look at each type in more detail.

Hard-Coat Low Emissivity Glass: Tough and Versatile

How Hard-Coat Low-E Is Made

With hard-coat Low-E, the coating is applied during the float glass manufacturing process:

- Molten glass floats on a bath of tin.

- While it’s still extremely hot, a metal-containing gas is sprayed onto the surface.

- The gas reacts with the hot glass, forming a tough oxide layer that’s essentially fused into the surface.

Because it’s baked on at such high temperatures, the coating becomes part of the glass itself.

Advantages of Hard-Coat Low Emissivity Glass

- High durability – can tolerate handling, cutting and processing without special care.

- Can be exposed – suitable for certain single-glazed or externally exposed applications.

- Cost-effective – generally cheaper per square metre than high-performance soft-coat products.

- Simple logistics – doesn’t have the same tight shelf-life and storage limitations.

This makes hard-coat Low-E a practical choice where:

- Budget is tight

- Glass may be exposed or single-glazed

- Extreme performance isn’t the top priority

Limitations of Hard-Coat Low-E

The pyrolytic process also has trade-offs:

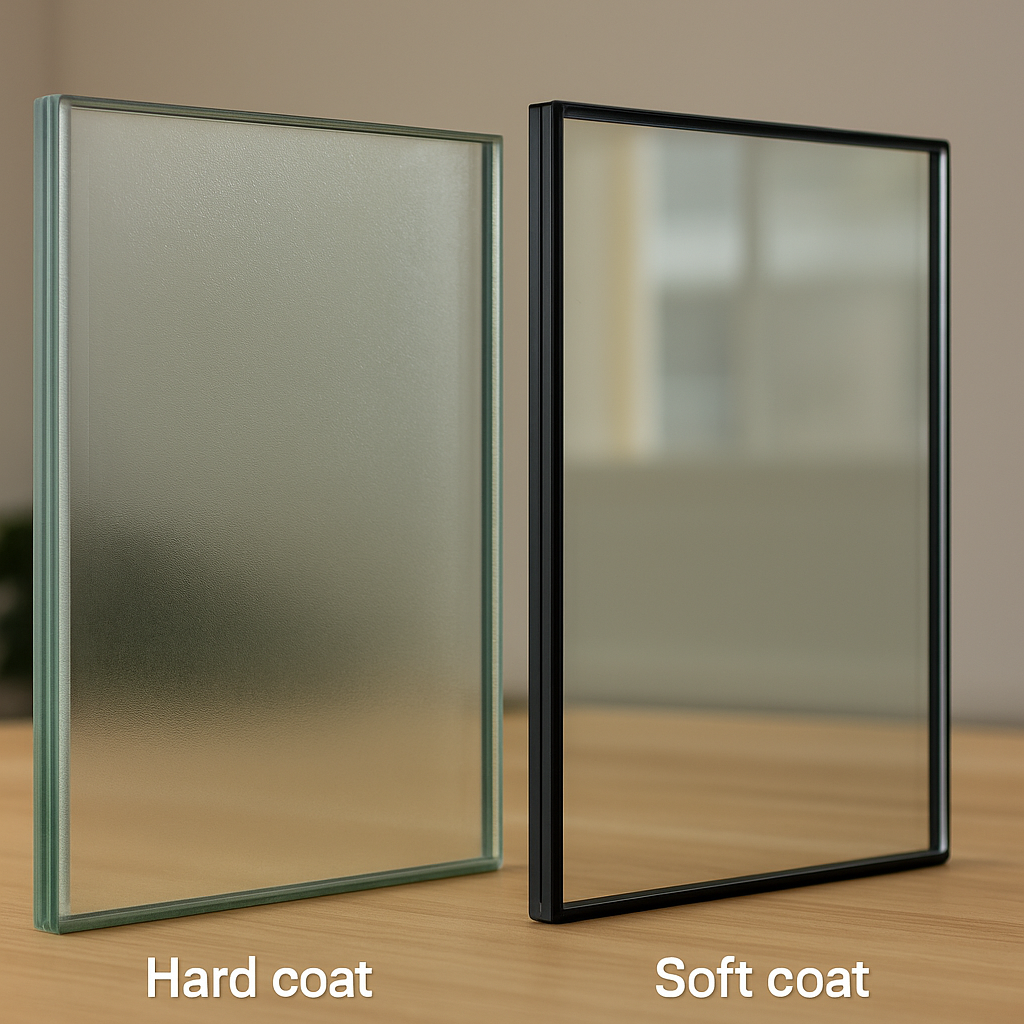

- Coatings are typically thicker, which can produce a slight haze or iridescence in certain light.

- Thermal performance is good, but not best-in-class – U-values and solar control are generally weaker than soft-coat alternatives.

- The range of solar-control and colour options is narrower.

Hard-coat Low-E is a solid all-rounder, but it doesn’t deliver the ultra-low U-values and fine-tuned solar control that many modern projects demand.

Soft-Coat Low Emissivity Glass: High Performance and High Clarity

How Soft-Coat Low-E Is Made

Soft-coat Low-E is produced using a process called magnetron sputter vacuum deposition (MSVD):

- Fully formed glass panels enter a series of vacuum chambers.

- Metal targets (like silver and metal oxides) are bombarded with ions, causing atoms to “sputter” off.

- These atoms deposit onto the glass surface in multiple ultra-thin layers.

By adjusting the materials and layer structure, manufacturers can fine-tune:

- Emissivity

- Solar heat gain

- Visible light transmission

- Colour and reflectivity

Advantages of Soft-Coat Low Emissivity Glass

- Best-in-class insulation – achieves much lower U-values than hard-coat products.

- Excellent solar control – versions with low SHGC can heavily reduce summer heat gain, while high-gain options allow beneficial winter sun in colder climates.

- High clarity – ultra-thin layers reduce haze; views are sharper and cleaner.

- Huge design range – multiple coatings with different performance and aesthetic options.

That’s why soft-coat Low-E is the go-to choice for:

- High-performance residential windows

- Energy-efficient commercial facades and curtain walls

- Projects targeting green ratings or strict energy codes

If your goal is maximum performance and comfort, soft-coat low emissivity glass is almost always the better option.

Limitations of Soft-Coat Low-E

- More delicate before assembly – unsealed coatings can oxidise if left exposed too long.

- Must be sealed inside a double or triple glazed unit (IGU).

- Requires careful handling and shorter shelf-life from production to final assembly.

- Usually more expensive than basic hard-coat alternatives.

In short: soft-coat Low-E gives you higher performance but needs more control in manufacturing and glazing.

Hard-Coat vs Soft-Coat Low Emissivity Glass: Key Differences

1. Durability and Handling

- Hard-coat: Extremely tough; can be used exposed, handled like ordinary glass, and often used in single glazing.

- Soft-coat: Delicate until sealed; must be handled carefully and encapsulated inside an IGU.

2. Thermal Performance (U-Values)

- Hard-coat: Good improvement over clear glass, but limited in how low U-values can go.

- Soft-coat: Can reach very low U-values, especially in double and triple glazing – ideal for high-performance envelopes.

To understand how that plays out in a whole home, see

How Does Low Emissivity Glass Improve Energy Efficiency in Homes?

3. Solar Control (SHGC)

- Hard-coat: Usually offers modest solar control; some products lean toward passive solar gain in cold climates.

- Soft-coat: Wide spectrum of options, from high-solar-gain coatings for cold regions to low-solar-gain coatings for hot climates and west-facing facades.

4. Visual Clarity and Appearance

- Hard-coat: Thicker layers can cause slight haze or colour shift in some conditions.

- Soft-coat: Ultra-thin, multi-layer stacks deliver clearer views and higher light transmission with more control over tint and reflectivity.

5. Cost and Value

- Hard-coat: Lower upfront cost; good where budget and durability matter more than ultimate performance.

- Soft-coat: Higher initial cost but often better long-term value from reduced energy bills, improved comfort and easier compliance with energy standards.

If you’re still weighing Low-E against basic glass, it’s worth reading

Why Is Low Emissivity Glass Better Than Clear Glass?

Choosing the Right Low Emissivity Glass for Your Project

Step 1: Understand Your Climate

- Cold climates:

- Look for passive soft-coat Low-E that allows solar gain (higher SHGC) but minimises heat loss.

- Hard-coat can work in simpler or cost-sensitive projects, but soft-coat will deliver better U-values.

- Hot or mixed climates:

- Favour solar-control soft-coat Low-E with lower SHGC to limit overheating.

- Hard-coat may struggle to match the solar control required for comfort and code compliance.

Step 2: Consider Building Type and Glazing Area

- Residential homes:

- Soft-coat Low-E in double glazing is now the standard for exterior windows and doors.

- Hard-coat may appear in garages, sheds or secondary spaces where energy performance is less critical.

- Commercial buildings:

- Large glass areas mean heat gain and loss add up fast, so soft-coat Low-E is usually essential.

- Curtain walls, offices, schools and hospitals benefit massively from advanced solar-control coatings.

Step 3: Think Holistically – Not Just About the Glass

Windows don’t work in isolation. Low emissivity glass performs best when it’s part of a broader design strategy that includes:

- Orientation and facade design

- Eaves, screens and operable shading

- Insulation and airtightness

- Outdoor elements like pergolas, trees and planting

Smart landscaping can shade glass in summer while letting in winter sun. For ideas on how landscape and glazing design can work together, see

Designers Define Landscape Trends in Modern Gardens

Specification Checklist: Hard-Coat vs Soft-Coat Low Emissivity Glass

When you’re ready to specify, use this quick checklist:

- Performance targets

- What U-value and SHGC do you need to meet code and comfort goals?

- Glazing build-up

- Single, double or triple glazing? (Soft-coat needs insulated units.)

- Location and exposure

- Is the glass subject to harsh sun, salt spray, or impact?

- Budget vs lifetime value

- Are you optimising for lowest upfront cost, or best long-term running cost?

- Aesthetic requirements

- Do you need a neutral appearance, low reflectivity or a specific colour tone?

In many modern projects, this process naturally leads to soft-coat low emissivity glass for primary glazing, with hard-coat reserved for specialised or cost-sensitive areas.

Final Thoughts: Two Technologies, One Goal

Hard-coat and soft-coat low emissivity glass were developed to solve the same problem: standard clear glazing leaks too much heat and lets in too much UV. They just take different paths to get there.

- Hard-coat Low-E is tough, practical and budget-friendly, ideal for simpler applications and exposed single glazing.

- Soft-coat Low-E is the high-performance choice, delivering superior insulation, solar control and clarity in modern double and triple glazing.

Whichever route you choose, moving from clear glass to Low-E is one of the most powerful steps you can take to reduce heat loss, control UV, and build more comfortable, energy-efficient spaces.

To explore the broader benefits in more detail, you can continue with

How Can Low Emissivity Glass Reduce Heat Loss and UV Damage?

and

How Does Low Emissivity Glass Improve Energy Efficiency in Homes?

Together, these insights make it clear: once you understand the difference between hard-coat and soft-coat, low emissivity glass stops being a mystery coating and becomes a precise, powerful tool in your design toolkit.