Low emissivity glass is no longer a “nice-to-have” upgrade — it’s one of the most important components in any energy-efficient building envelope. Yet not all low-E products perform the same. Two windows can look identical on the facade, but one can dramatically reduce heat loss and solar gain while the other only offers marginal improvement.

So what actually helps different low emissivity glass types achieve higher thermal efficiency? It comes down to how the coating is made, where it’s positioned, how the insulating glass unit (IGU) is built, and how the whole system is specified and installed.

This guide breaks all of that down in practical language so you can choose and specify the right solution for your home or project.

Understanding Low Emissivity Glass and Thermal Efficiency

Before digging into types, it helps to understand what low emissivity glass is really doing.

Emissivity and the solar spectrum

Solar energy arrives in three main bands:

- Ultraviolet (UV) – short wavelengths that cause fading of fabrics and finishes.

- Visible light – the daylight we actually want to keep.

- Infrared (IR) – perceived as heat, separated into:

- Short-wave IR from the sun

- Long-wave IR radiated from warm objects (people, heaters, warm glass)

Plain clear glass has a relatively high emissivity (around 0.84), which means it readily absorbs heat and re-radiates it to the colder side. That’s why a standard window feels icy in winter and hot to stand beside in summer.

Low emissivity glass adds an ultra-thin metallic coating — often silver or metal oxides — that:

- Reflects long-wave IR back toward its source

- Can also reflect part of the short-wave solar IR

- Still allows a high level of visible light through

The result: far less radiant heat transfer, which shows up in lower U-values (better insulation) and better solar heat gain control.

Key Low E Glass Types That Drive Thermal Performance

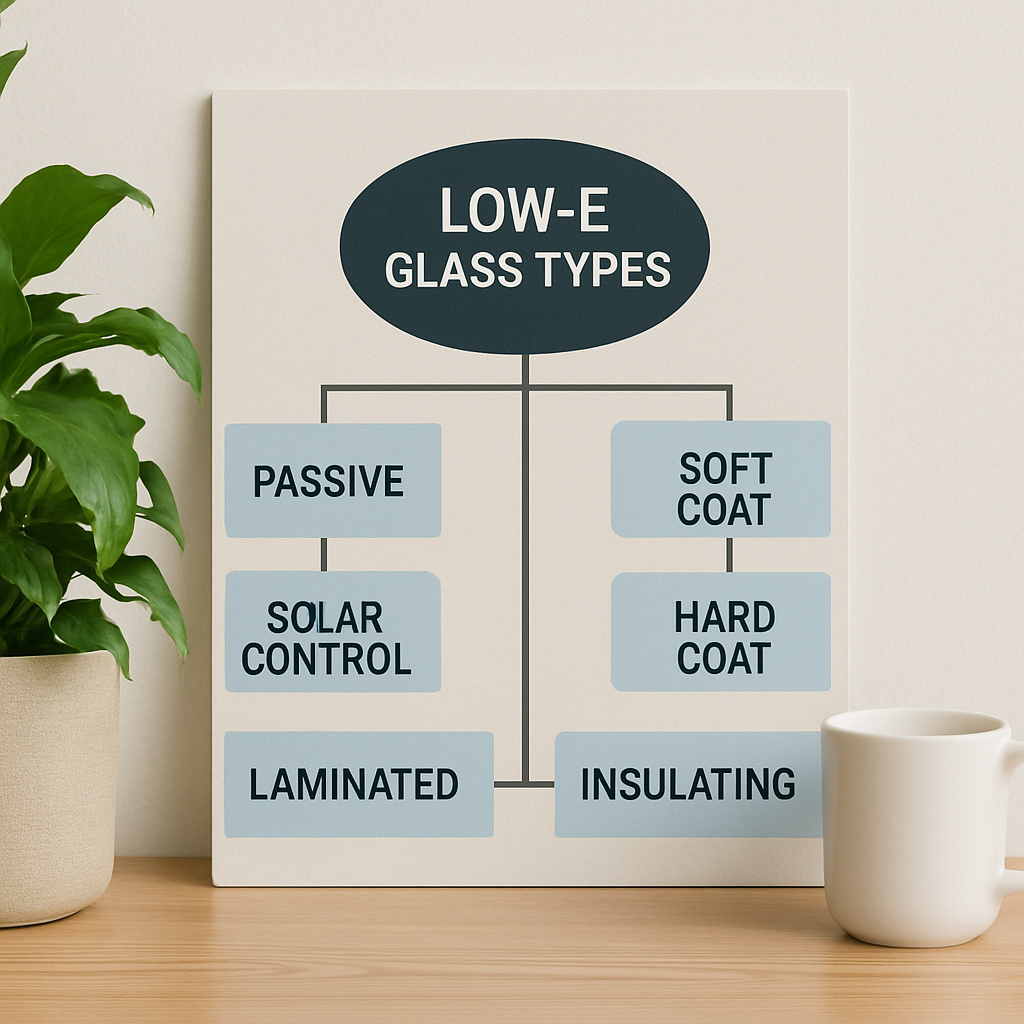

When people talk about “types” of low-E, they usually mean one of three things:

- Passive vs solar-control low-E coatings

- Hard-coat vs soft-coat manufacturing

- Where the coating is placed inside the IGU

Each of these choices has a direct impact on thermal efficiency.

1. Passive vs solar-control low-E

Passive low emissivity glass

- Designed to maximize useful solar heat gain in cold or heating-dominated climates.

- Lets in more short-wave IR from the sun while still reflecting room heat back inside.

- Typically has:

- Lower U-value than clear glass

- Higher Solar Heat Gain Coefficient (SHGC) than solar-control low-E

- Best for:

- North-facing facades in the Southern Hemisphere / south-facing in the Northern Hemisphere

- Cold climates where winter solar gain is desirable

Solar-control low emissivity glass

- Engineered to limit solar heat gain in hot or cooling-dominated climates.

- Reflects more short-wave IR, reducing overheating and AC loads.

- Typically has:

- Low U-value

- Low SHGC, helping keep interiors cooler

- Best for:

- East, west, and sometimes north/south facades with strong sun

- Warm or mixed climates where cooling loads dominate

In short: Passive low-E boosts free winter heat; solar-control low-E cuts unwanted summer heat. Choosing the right family is the first big lever for thermal efficiency.

2. Hard-coat vs soft-coat low-E

The manufacturing process also changes how well low emissivity glass performs.

Hard-coat (pyrolytic) low-E

- Coating applied while glass is still hot on the float line.

- Fuses into the surface → very durable and easy to handle.

- Can be exposed (single glazing, laminated exterior lite).

- Typically:

- Higher emissivity (worse insulation than best soft-coats)

- Higher SHGC (more solar gain)

Where it helps thermal efficiency:

- Budget-conscious projects that still want a step up from clear glass

- Single glazing where double or triple IGUs aren’t possible

- Cold climates that benefit from extra solar gain

Soft-coat (MSVD) low-E

- Applied in a vacuum chamber to already-formed glass.

- Many nano-thin layers (often including silver) tailor optical and thermal properties.

- More delicate → must be sealed inside an IGU.

- Typically:

- Very low emissivity (excellent insulation)

- Tunable SHGC (from high-gain to deep solar-control)

- Higher light-to-solar-gain ratios (more daylight per unit of heat)

Where it helps thermal efficiency most:

- High-performance double or triple glazing

- Projects targeting low U-values and strict energy codes

- Mixed or hot climates needing strong solar control without dark interiors

If your goal is maximum thermal efficiency, soft-coat low emissivity glass in an IGU is usually the winning choice.

3. Coating location inside the IGU

In a standard double-glazed unit, we label glass surfaces like this:

- #1 surface – outer face, exposed to the weather

- #2 surface – inner face of the outer pane (inside the cavity)

- #3 surface – outer face of the inner pane (inside the cavity)

- #4 surface – inner face, facing the room

Where the low emissivity glass coating sits makes a big difference.

- Solar-control low-E → usually on the #2 surface

- Stops solar heat before it penetrates far into the unit

- Best for cooling-dominated designs

- Passive low-E → often on #3 or #4 surface

- Keeps interior heat inside while allowing solar gain

- Best for heating-dominated facades

In triple glazing, you can combine coatings on the #2 and #5 (or #3 and #5) surfaces to fine-tune SHGC and U-value. Correct surface placement is one of the biggest “hidden” optimizers of thermal efficiency.

For more detail on positioning and specification strategy, it’s worth reviewing How to Specify Low Emissivity Glass in Architecture as part of your design workflow.

Other Factors that Help Low E Glass Achieve Higher Thermal Efficiency

Once you’ve chosen coating type and position, several additional design choices push performance even further.

4. Double vs triple glazing

- Double glazing with low emissivity glass

- Major improvement over single glazing

- Typical U-values around 1.0–1.4 W/m²·K depending on gas fill and spacer

- Triple glazing with low emissivity glass

- Adds a second insulating cavity

- U-values can drop below 0.8 W/m²·K with the right low-E stack and gas

- Ideal for very cold climates or ultra-low-energy buildings

For high solar-gain homes in colder regions, combining passive low-E with triple glazing can mean panoramic glass facades without comfort penalties. If you’re tuning specifically for sun-rich sites, you can also dive into Which Low E Glass Types Work Best for High Solar Gain Homes? for more climate-specific guidance.

5. Gas fills and warm-edge spacers

The cavity between panes is just as important as the glass:

- Argon

- Most common upgrade

- Lower thermal conductivity than air at a reasonable cost

- Krypton

- Better insulator in narrow cavities

- Often used in triple glazing or slimline heritage units

Then there’s the spacer:

- Aluminium spacers conduct heat easily → “cold edge” and higher U-values

- Warm-edge spacers (stainless, composite, foam) reduce edge losses and condensation

Pairing low emissivity glass with argon/krypton and warm-edge spacers can reduce whole-window U-values by 10–20% compared with air-filled, aluminium-spacer IGUs.

6. Frame material and design

Even the best low emissivity glass can’t save a poorly performing frame. Thermal efficiency is always measured for the full window:

- Thermally broken aluminium frames cut conductive heat paths

- uPVC and fiberglass frames offer good insulation with low maintenance

- Timber frames have strong thermal performance but need protection and detailing

Look for:

- Continuous thermal breaks

- Multi-chambered profiles

- Quality gaskets and compression seals

When specifying, align frame U-values with your glass choice; there’s little point paying for a top-tier low-E IGU if it’s installed in a highly conductive frame.

7. Airtightness and installation quality

A high-performance IGU only delivers its rated efficiency when it’s:

- Correctly sized and packed in the sash

- Properly sealed with tapes/foams and interior air-tight layers

- Protected from unintended thermal bridges around the frame

Poor installation can easily add 20–30% to actual heat loss through leaks and cold spots. For a deeper dive into field practice, pair design decisions with the guidance in What Steps Ensure Low Emissivity Glass Is Installed Correctly? so the performance on paper is the performance you get on site.

Balancing Efficiency with Daylight, Views and Acoustics

Pursuing ultra-low U-values is only part of the story. Great facades balance thermal efficiency with:

- High Visible Light Transmittance (VLT) for bright spaces

- Comfortable Solar Heat Gain Coefficient (SHGC) to avoid glare and overheating

- Good acoustic control, especially in urban locations

Modern multi-silver soft-coat low-E products can hit impressive light-to-solar-gain ratios, meaning:

- Plenty of useful daylight

- Limited unwanted heat

- Minimal visible tint or colour shift

If you’re tuning the envelope for both comfort and efficiency, Low Emissivity Glass and Its Daylight–Solar Control Balance is a useful companion read. And in noisy environments, combining low-E coatings with laminated or hybrid acoustic build-ups can dramatically improve sound insulation — see How Low Emissivity Glass Improves Indoor Acoustics? for design ideas.

At the precinct scale, smarter envelopes are also one part of broader sustainable city thinking, alongside shading, greenery and micro-climate strategies explored in Define Landscape Solutions in Smart Cities.

Practical Steps to Maximize Thermal Efficiency with Low Emissivity Glass

To pull everything together, here’s a simple workflow when you’re selecting low emissivity glass for higher thermal efficiency:

- Clarify the climate and facade orientation

- Heating-dominated? Favour passive low-E with higher SHGC on sun-facing elevations.

- Cooling-dominated or mixed? Use solar-control low-E with lower SHGC on exposed facades.

- Choose the coating technology

- Hard-coat low-E for budget upgrades and single glazing.

- Soft-coat low-E for high performance double or triple glazing.

- Specify coating location in the IGU

- Solar-control low-E on #2 surface.

- Passive low-E on #3 or #4 (and #5 in triples).

- Select glazing build-up

- Double vs triple glazing based on energy targets and climate.

- Add argon/krypton fills and warm-edge spacers.

- Match the frame to the glass

- Thermally broken, well-sealed frames with compatible U-values.

- Detail airtight installation

- Include tapes, gaskets, and continuity of the air barrier in the spec.

- Insist on certified installers and quality checks.

- Review whole-window performance, not just centre-of-glass

- Compare U-value, SHGC, VLT and light-to-solar-gain to ensure you’re hitting both comfort and energy goals.

Conclusion

What really helps low emissivity glass types achieve higher thermal efficiency isn’t a single magic feature – it’s the way the coating, glass build-up, frame and installation all work together.

- Passive and solar-control low-E coatings target different climates and facades.

- Soft-coat multi-layer stacks unlock the lowest emissivity values and best energy performance.

- Correct surface placement, gas fills, warm-edge spacers and thermally sound frames turn that potential into real-world savings.

- Thoughtful specification and careful installation ensure those gains aren’t lost to air leakage or thermal bridges.

If you treat low emissivity glass as a full system — not just a buzzword in the spec — you can dramatically cut heating and cooling loads, improve comfort, and future-proof your projects against tightening energy codes.