Getting the position of low emissivity glass right inside an insulating glass unit (IGU) is just as important as choosing the coating itself. You can specify the best Low-E product on the market, but if it’s installed on the wrong surface, you’ll leave energy savings, comfort and UV protection on the table.

This guide explains exactly where low emissivity glass should sit in both double- and triple-glazed IGUs, and how the “right” position changes for solar control Low-E vs passive Low-E coatings.

First: What Is an IGU and How Are Surfaces Numbered?

An insulating glass unit (IGU) is made from multiple panes of glass separated by spacer bars and sealed around the edges to create one airtight unit. The gaps between panes are usually filled with air or an inert gas (such as argon or krypton) to improve insulation.

To talk about Low-E positioning, we number the glass surfaces from outside to inside:

Double-glazed IGU

- Surface 1 – Outside face of the exterior pane

- Surface 2 – Inside face of the exterior pane

- Surface 3 – Outside face of the interior pane

- Surface 4 – Inside face of the interior pane (facing the room)

Triple-glazed IGU

- Surface 1 – Outside face of outer pane

- Surface 2 – Inside face of outer pane

- Surface 3 – Outside face of middle pane

- Surface 4 – Inside face of middle pane

- Surface 5 – Outside face of inner pane

- Surface 6 – Inside face of inner pane (facing the room)

Low-E coatings are always placed inside the cavities, never on the fully exposed outer surface, so they’re protected from weathering and cleaning damage.

Solar Control vs Passive Low Emissivity Glass

Before you decide “where,” you need to know which type of Low-E you’re using.

Passive Low-E

- Designed primarily for cold or heating-dominated climates

- Lets more solar heat into the building while still reducing heat loss

- Ideal when you want to capture winter sun for passive heating

Solar Control Low-E

- Designed for warm or mixed climates and sun-exposed façades

- Strongly limits solar heat gain while still providing good insulation

- Helps prevent overheating and reduces cooling loads

These two families behave differently, so their optimal surface positions inside an IGU are not the same.

For more detail on how different coatings are made and why they behave the way they do, you can refer to

Low Emissivity Glass Hard-Coat and Soft-Coat.

Best Low Emissivity Glass Positions in Double-Glazed IGUs

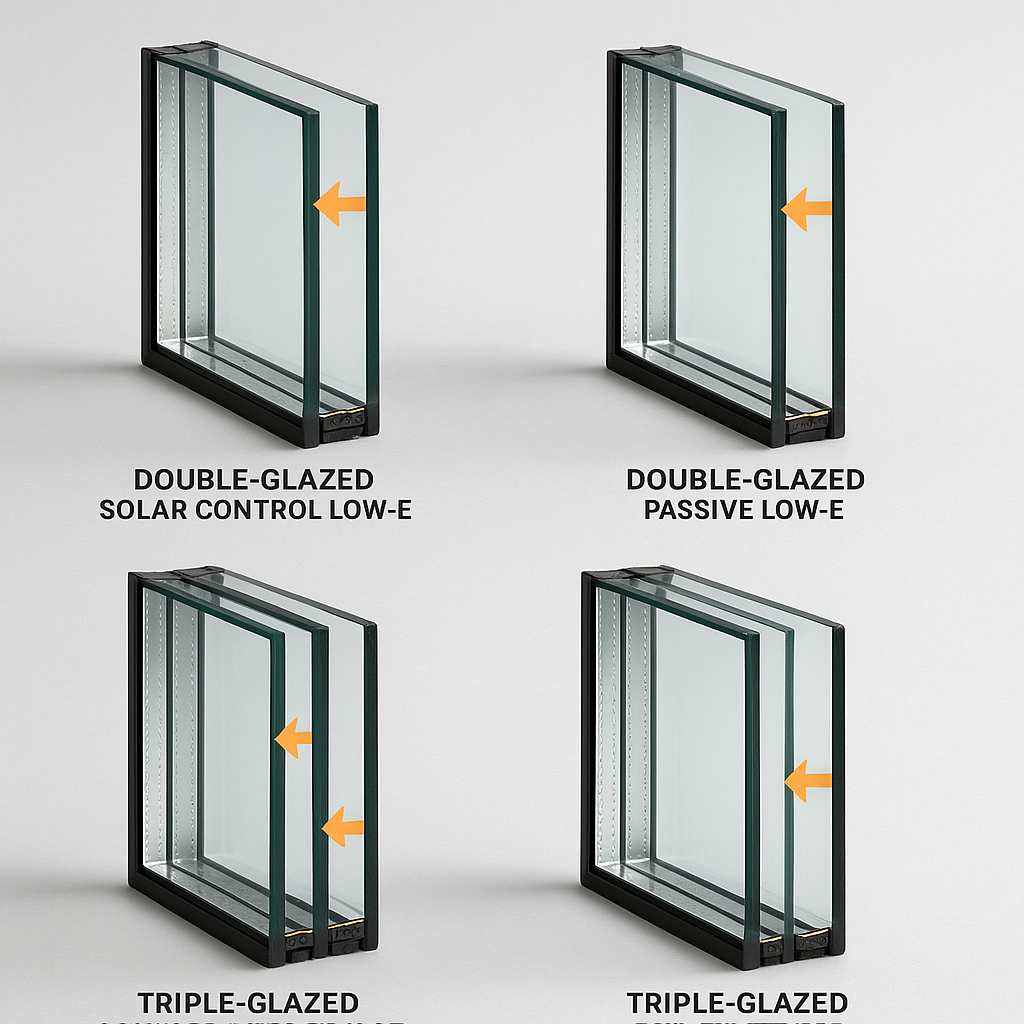

1. Double-Glazed with Solar Control Low-E

For solar control Low-E in a standard double-glazed unit, the optimal position is:

- Primary Low-E coating on Surface 2

Why?

- Surface 2 is just behind the exterior face, so it “sees” the sun first.

- The coating can reflect a significant portion of solar infrared back outside before it enters the cavity, cutting unwanted solar gain.

- Visible light still passes through, so you retain natural daylight.

To boost performance further:

- Fill the cavity with argon gas to reduce conductive heat transfer.

- Optionally add a second Low-E coating on Surface 4 (the room-side inner surface). A “double-Low-E” configuration tightens U-values and improves winter insulation.

This setup works especially well for:

- Hot and mixed climates

- North- and west-facing façades (in the southern hemisphere; south/west in the northern hemisphere)

- Large glazed areas or curtain walls with strong sun exposure

2. Double-Glazed with Passive Low-E

For passive Low-E coatings in double glazing, the goal is to admit useful solar heat while limiting heat loss. The ideal placement is:

- Primary passive Low-E coating on Surface 3 or 4 (on the pane closer to the interior)

Commonly:

- Surface 3 if you want a balance of solar gain and reduced heat loss

- Surface 4 where maximum winter heat retention is the priority

This configuration:

- Lets the sun’s short-wave radiation enter and warm internal surfaces

- Reflects long-wave heat back into the room once it’s inside

- Is particularly effective in cold or heating-dominated climates

Again, adding argon fill and possibly a second coating on Surface 4 can enhance performance further.

Best Low Emissivity Glass Positions in Triple-Glazed IGUs

Triple-glazed units add a third pane and a second cavity, giving more options for coating placement and even lower U-values.

If you haven’t yet, it’s worth reading

Low Emissivity Glass Performs in Triple-Glazed Systems?

for a broad overview before getting into surface-specific layouts.

1. Triple-Glazed with Solar Control Low-E

In solar control triple glazing, you want to limit solar gain strongly while maintaining excellent insulation. The recommended configuration is:

- Solar control Low-E coatings on Surfaces 2 and 4

Why this works:

- Surface 2 handles most of the incoming solar radiation, reflecting IR heat before it penetrates deeply into the unit.

- Surface 4 acts as a second “thermal mirror,” reflecting additional heat back toward the outside cavity, tightening the U-value and further reducing solar gain.

To squeeze out a bit more performance:

- Use argon (or krypton) gas in both cavities.

- Optionally add a third Low-E coating on Surface 6. The improvement is modest but can help meet very strict performance targets.

This layout is ideal for:

- High-performance homes in hot or mixed climates

- Large areas of glass in sun-exposed orientations

- Projects targeting very low cooling loads or net-zero energy goals

2. Triple-Glazed with Passive Low-E

For passive Low-E in triple glazing, the goal flips: you still want minimal heat loss, but also useful solar gain where climate allows. A typical arrangement is:

- Primary passive Low-E coating on one of the inner-pane surfaces (often Surface 4 or 5)

In practice:

- Surface 4 captures interior heat and reflects it back into the room

- Surface 5 can be used to further control heat loss while allowing solar gain from the outer layers

For ultra-high performance:

- Add argon in both cavities

- Consider a second or third Low-E coating on Surface 6 to shave U-values down even further

This building-block approach is what allows triple-glazed passive units to achieve extremely low heat-loss values, making them popular in cold climates, alpine environments, and Passive House projects.

Why Surface Position Matters So Much

Placing low emissivity glass on the “wrong” surface doesn’t mean the window won’t work—but it can mean:

- Lower than expected energy savings

- More glare or overheating in summer

- Reduced comfort near windows on cold nights

- Less effective UV protection for internal finishes

Correct placement ensures that the Low-E coating is “looking” in the right direction:

- Solar control coatings should face the source of unwanted solar heat.

- Passive coatings should sit where they can capture and re-radiate indoor warmth most effectively.

If you’re still comparing Low-E glazing with basic clear glass, you’ll find a helpful baseline in

Why Is Low Emissivity Glass Better Than Clear Glass?.

Other Factors That Influence IGU Performance

Getting Low-E position right is crucial, but not the only piece of the puzzle.

1. Gas Fill and Spacer Design

- Argon is the most common upgrade from air; it’s affordable and significantly improves insulation.

- Krypton can deliver even better performance in narrower cavities but at a higher cost.

- Warm-edge spacers reduce thermal bridging at the perimeter of the IGU, further improving U-values and reducing condensation risk.

2. Frame Material and Installation

Even the best IGU will underperform if it’s sitting in a poorly insulated frame or badly sealed opening. Look for:

- Thermally broken aluminium, timber, uPVC or composite frames

- Continuous air- and weather-sealing around the window perimeter

- Correct packers and fixings to avoid frame distortion that can compromise the IGU seal

3. Orientation, Shading and Surrounding Design

Orientation and shading strategies should always be considered alongside Low-E placement:

- North- or south-facing elevations (depending on hemisphere) may benefit from different Low-E and shading strategies than east/west façades.

- External shading devices, eaves, fins and screens are powerful allies in managing solar gain.

- Landscaping—trees, pergolas, and garden structures—can also provide seasonal shade and cooling.

For inspiration on how outdoor design can complement high-performance glazing, see

Designers Define Landscape Trends in Modern Gardens.

Putting It All Together: A Simple Decision Framework

When planning where to position low emissivity glass in an IGU, work through these steps:

- Define your climate and priorities

- Heating-dominated? Favour passive Low-E on the inner panes.

- Cooling-dominated? Use solar control Low-E on the exterior-facing panes.

- Choose double or triple glazing

- Double glazing + Low-E is usually sufficient for mild to moderate climates.

- Triple glazing with multiple Low-E coatings suits harsher climates or ultra-low-energy builds.

- Assign surfaces based on coating type

- Solar control in double glazing → Surface 2 (plus optionally Surface 4).

- Passive in double glazing → Surface 3 or 4.

- Solar control in triple glazing → Surfaces 2 & 4 (optionally 6).

- Passive in triple glazing → Inner lites (4/5), optionally 6.

- Enhance with gas fills and warm-edge spacers

- Prefer argon or krypton over plain air.

- Check compatibility with frame, orientation and shading

- Ensure the glazing strategy works with the whole building envelope, not just the glass.

If you’re planning a high-performance build or renovation that includes triple glazing, it’s worth reading

Low Emissivity Glass Performs in Triple-Glazed Systems?

alongside this article so you can match coating placement to real-world configurations.

Conclusion

The question “Where should low emissivity glass be positioned inside an IGU?” doesn’t have a one-size-fits-all answer—but the principles are consistent:

- Solar control Low-E belongs closer to the exterior to block unwanted solar heat.

- Passive Low-E belongs closer to the interior to trap warmth and support passive solar gains.

- The more panes and cavities you introduce (double vs triple glazing), the more finely you can tune performance with multiple coatings and gas fills.

Once you understand surface numbering and coating behaviour, Low-E placement becomes a powerful design tool rather than a mystery. Get it right, and your IGUs will deliver the comfort, efficiency and clarity that modern buildings demand.